- Systems

- Equipment

- Services

- Industries

- About Us

- Resources

- Contact Us

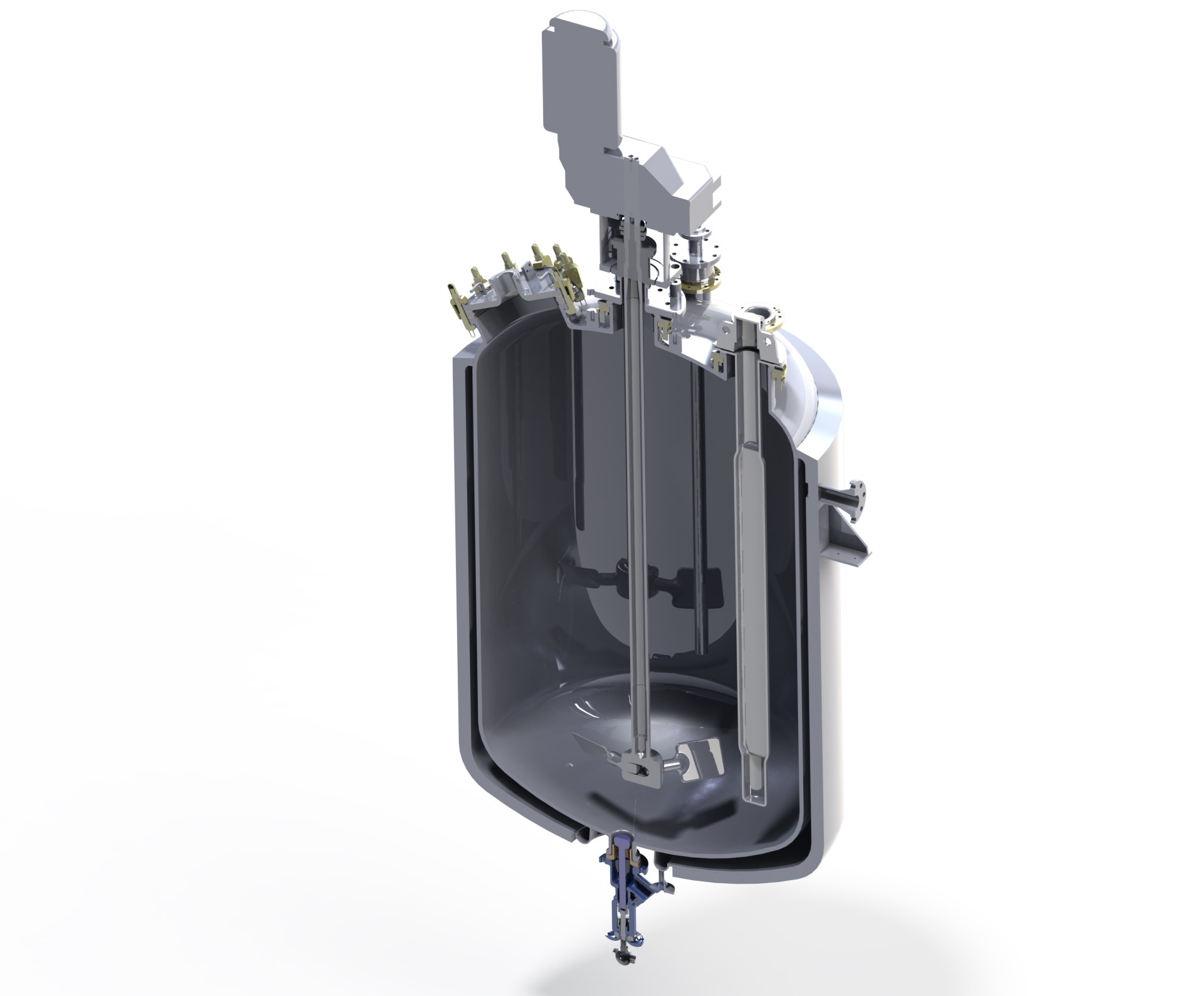

De Dietrich Process Systems offers multiple baffle options to complement your mixing system, providing optimized performance and process results.

.jpg?width=1094&height=838&name=OptiMix%20Reactor%20(1).jpg)

A baffle is an integral part of the mixing system that promotes better flow of fluids for maximum efficiency. Its primary function is to prevent the swirling in agitation by converting the swirling into a desired flow pattern. In addition to improved mixing, baffles can increase heat transfer and chemical reaction rates. Baffles also aid in decreasing vortex formation, increasing the power input of the agitator, and improving mechanical stability.

DDPS’ two main styles of baffle include a traditional flange-mounted design and an upgraded wall-mounted system. If you are looking for additional process functionality, we can also supply baffles that include peripheral instrumentation to meet supplementary process needs.

A baffle is an integral part of the mixing system that promotes better flow of fluids for maximum efficiency. Its primary function is to prevent the swirling in agitation by converting the swirling into a desired flow pattern. In addition to improved mixing, baffles can increase heat transfer and chemical reaction rates. Baffles also aid in decreasing vortex formation, increasing the power input of the agitator, and improving mechanical stability.

DDPS’ two main styles of baffle include a traditional flange-mounted design and an upgraded wall-mounted system. If you are looking for additional process functionality, we can also supply baffles that include peripheral instrumentation to meet supplementary process needs.

OptiMix is a patented baffle design that optimizes the mixing performance of glass-lined reactors by integrating three baffles on the vessel wall. This design enhances heat transfer, solids suspension and distribution, gas dispersion, gas flow rates, and mass transfer through improved mixing, making it a preferred design for chemical and pharmaceutical applications. It also eliminates the need for top entry baffles, freeing up an additional nozzle for process use.

Additionally, a new enhancement to the design, called OptiMix-HE, circulates the thermal fluid contained in the half-coil reactor jacket through the baffles for even more process optimization. OptiMix-HE increases heat transfer area 25% or more, enabling better homogeneity, faster thermal management, and shortened cycle times.

The high performance, flange-mounted BeaverTail baffle features no-entry installation and removal. The flange-mounted design reduces the possibility of leaks through gaskets or packing, since only one gasket is required for a seal. Further testing of the design shows performance of the BeaverTail baffle is superior to finger baffles and equivalent to “h”-style baffles at any liquid level. At liquid levels one-quarter full or less, BeaverTail baffle performs far superior to any of these older configurations.

The innovative combination dip pipe/baffle provides three functions in one piece of equipment:

DE DIETRICH PROCESS SYSTEMS is the leading global provider of Process Equipment, Engineered Systems and Process Solutions for the fine chemical, chemical and pharmaceutical industry.

Quick Links