4 Pieces of Advice before Starting your Next CPI Project

Starting any new project can be overwhelming. From reorganizing your garage to planning a large event, there are many details that need to be considered. It’s quite intimidating to be at square one and imagine how you are going to get to the finish line when there are so many obstacles you’ll inevitably encounter along the way. And when there are multiple items that need to be worked on, it’s daunting to figure out the right order in which to tackle each task.

This is true ten-fold if you are a project manager or process engineer who is responsible for designing, commissioning, and implementing a complex, new operation/process/system for your company (that can sometimes be a multi-million dollar project!). There are so many specifications and requirements that need to be taken into account, plus you are working on someone else’s timeline and budget so the pressure is on you to make sure the end product accomplishes the necessary objectives while adhering to the constraints you are given.

We have four pieces of advice to offer that can help anyone in this position who is either starting a new project or in the middle of one and could use some guidance. These tips will help your project to run smoothly and save you a lot of headaches and hassles.

1. Get out of the “equipment” mindset and start thinking about a “system”

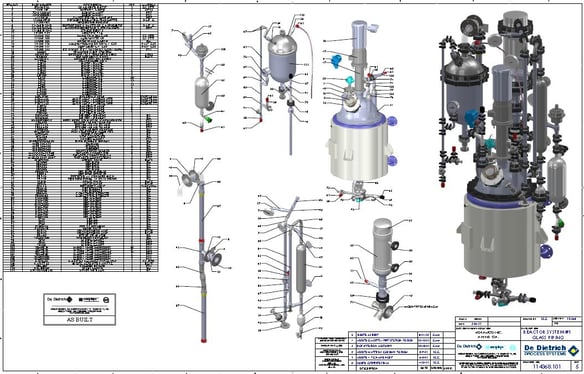

If your operation involves a series of steps and several pieces of equipment, it can be difficult to choose a starting point for your research and equipment procurement. There are multiple vendor comparisons and technologies to evaluate, and then you have to ascertain which is the best fit for your company. While you may want to focus on a few core pieces of equipment that are deemed the most critical players in the process, every part has its own role to play. From the small peripheral piece of instrumentation to the large reactor unit that is the heart of your operation, all of the components need to work together. Big or small, each piece of equipment has its own function and purpose in the process and will work more cohesively if they are properly integrated. To ensure this, you have to approach the project as one comprehensive system rather than looking at it as dozens of individual parts.

2. Streamline your project efficiency with a single source solution

What if I told you there was a way to make your job a whole lot easier that would not only help to minimize your workload but actually improve virtually every aspect of your project? If you are like most people that have an ever growing to-do list and not enough hours in the day to complete it, a “one-stop shop” is an invaluable resource for your project management. With a single source solution, you can have one vendor handle the details of your entire project from design and engineering, ancillary sourcing and procurement to integration of equipment, validation and testing, installation, and start-up support. Once you find a manufacturer that offers the technology needed for your process, they can save you time and money by coordinating all the particulars from soup to nuts, even outsourcing equipment and parts that aren’t in their wheelhouse. There is also a promise of compatibility when a manufacturer makes a commitment to you that the equipment will integrate properly into a system they are commissioning. If you are managing all of the procurement on your own with multiple vendors it increases your chances of unforeseen issues to arise. And you know who is responsible for those issues? That’s right, you are! Oversites in engineering and inaccuracies in planning can turn into costly mistakes, especially when they are not caught early on.

3. Go modular

Skid-mounted systems are often preferred over traditionally designed arrangements as they more effectively fit small spaces, an issue faced by many facilities that have big plans but little headroom to install them. In addition, modular designs are generally more cost effective, especially when you factor in transportation and installation expenses. All of these efficiencies work together to improve delivery times, which comes in handy when you are working with a strict project deadline and are limited on time. But that’s not all, modular designs enable faster installation and start-up. So let’s sum this up – looking for a way to best manage your space, budget, and time constraints? Modularization may be just the solution you need. Check out this excerpt from our glass-lined reactor animated video that features a great example of a modular system:

4. Consider process optimization recommendations

An easy way to increase expenses is through purchasing the bells and whistles in addition to the “base model”. While there are many options that come with some types of products that just improve its appearance, there are other performance enhancing options that could have a positive effect on your process and should therefore be evaluated when you are designing your system. For example, OptiMix baffles might be presented to you as an upgraded option for your reactor. Because you are conscious of your limited budget, you might initially plan to use the standard, flange-mounted baffle. However, if you take into account the benefits of OptiMix (improved mixing and heat transfer rates) you can begin to see the long term benefits it will provide (shortened batch time and increased yield). Further evaluation and calculations can show that the boost in productivity equates to more profitability for your company. While you won’t choose every available option, it’s important to understand what enhancements are available so you can determine which ones are worth your investment to improve the overall performance of your system.

Regardless of the resources available to you, managing a new project is a huge undertaking. De Dietrich Process Systems can help with that by offering pre-packaged units and customized solutions across a wide range of technologies. What this video for an animated look at our systems capabilites:

Our Engineered Systems team of experts can partner with you in your project management so you can be assured your project will run smoothly from start to finish. Contact DDPS to find out more about our capabilities and services and how they relate to your technical needs.