Are there different types of pneumatic conveying systems?

There are two general classifications for pneumatic transfer. Once you’ve decided pneumatic conveying is the right solution for your process, understanding these modes of operation can help you to further distinguish which method of conveying is better suited for your application.

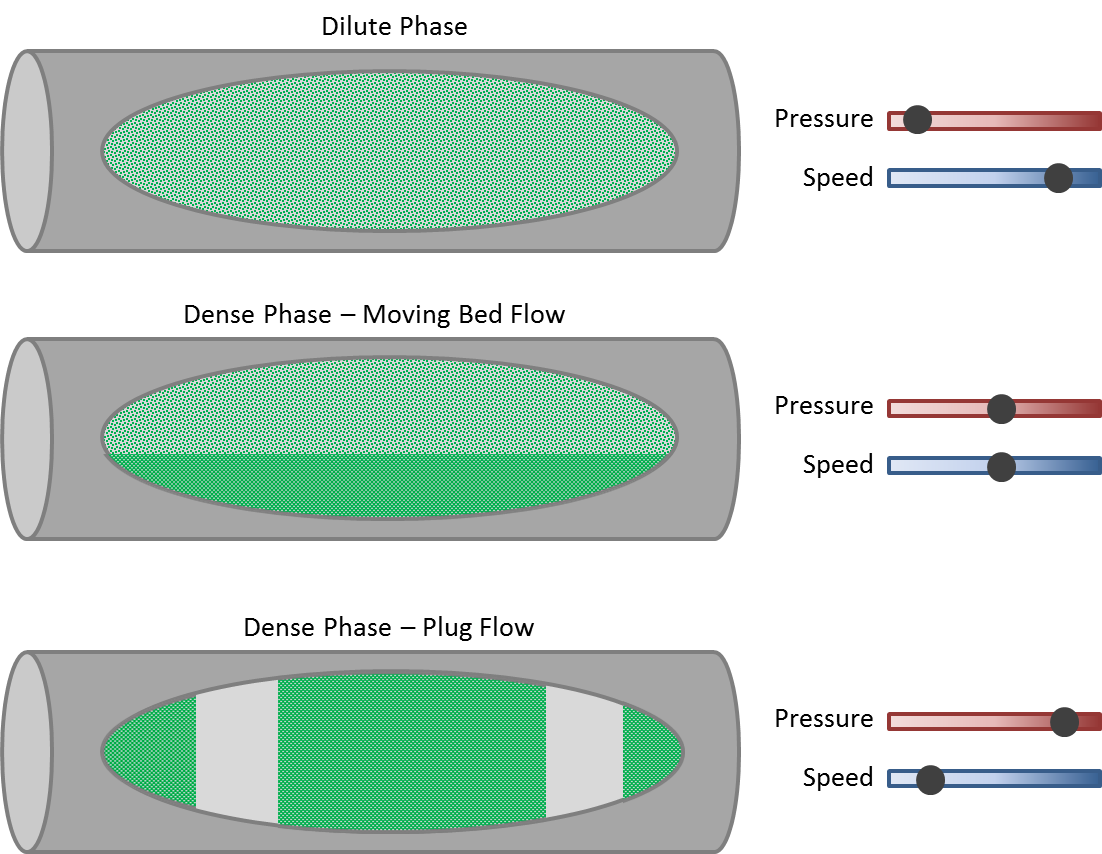

Dilute phase or lean phase conveying takes place when material is suspended in air as it is blown or sucked through a pipeline. Virtually all material can be conveyed via this mode, regardless of particle size, shape or density. However, a relatively high velocity is required, which consumes large amounts of energy. Particles that are abrasive are not recommended to be transferred in this way as they can cause damage and erosion to the pipeline. Similarly, products that can be easily crushed or broken should not be transferred in this manner due to their fragility.

Dense phase conveying, on the other hand, moves material at a lower velocity in a non-suspension mode. There are two types of flow that are produced by this method of conveying:

· In moving bed flow, material is transported along the bottom of the pipeline. This type of flow is limited to material that has good air-retention characteristics, such as very fine powdered materials like fly ash, cement, or flour.

· In plug flow, material is transferred as full bore plugs separated by air gaps. This type of flow is possible when the material has good permeability. Pellet sized materials and seeds are ideal candidates for this type of flow.

The following diagram depicts the different phases of pneumatic conveying and the pressure/velocity associated with each type of flow: