Plugs

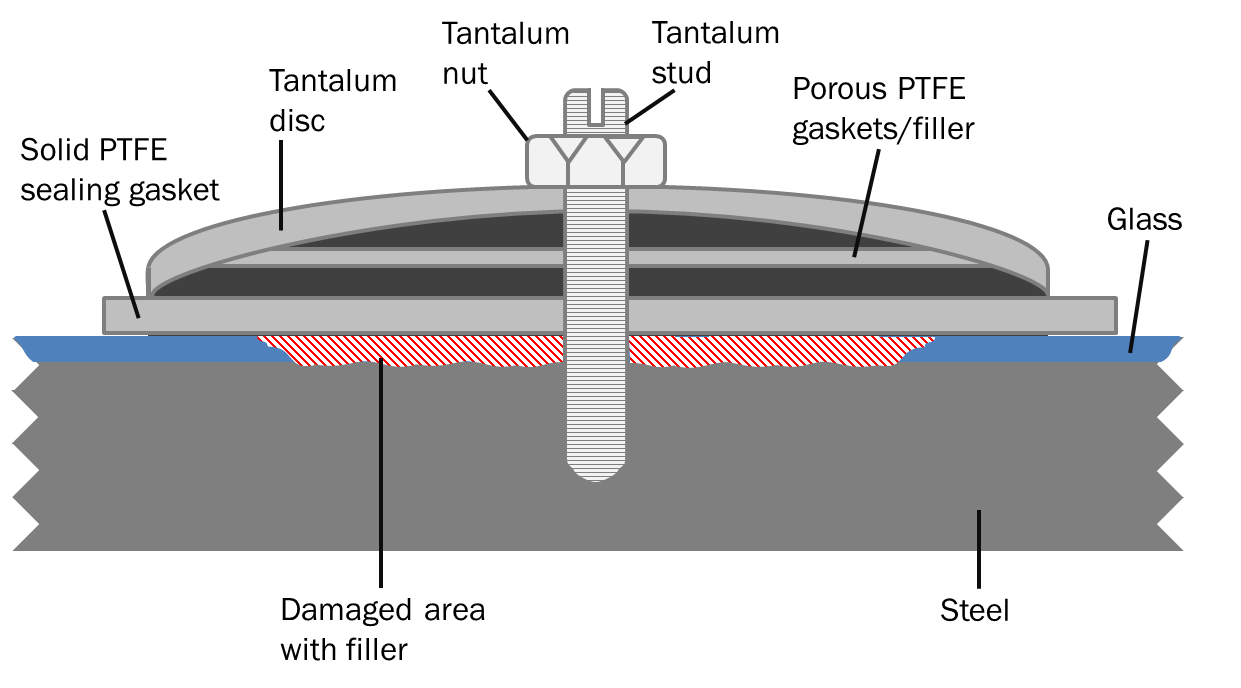

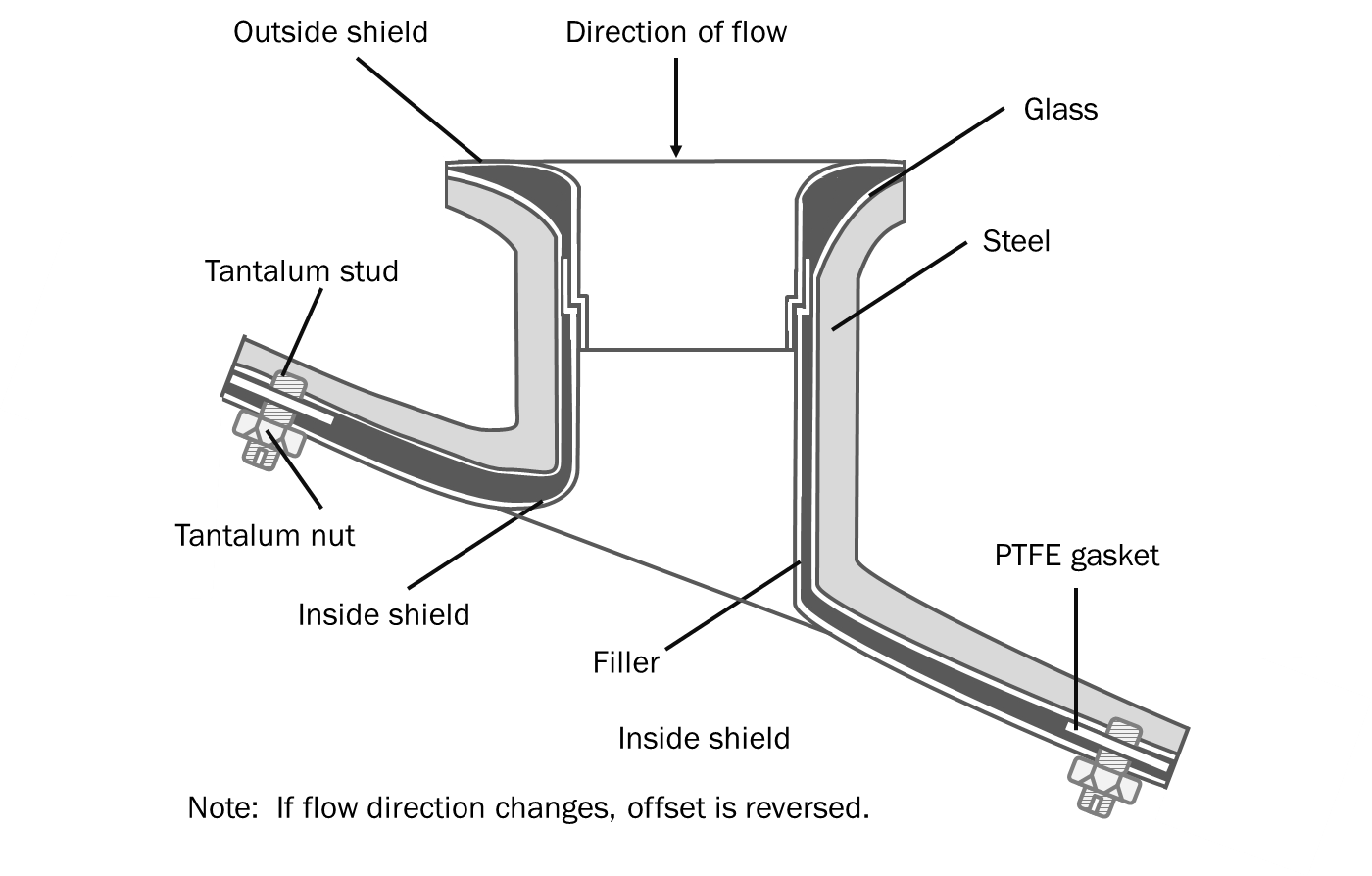

When a minor defect is found in a new vessel prior to factory shipment, or when there is a small area that was damaged by internal or external mechanical impact, a plug is most frequently used to repair it. The two types available are a one-piece plug which consists of a metal stud (usually tantalum) and a PTFE gasket and a three-piece plug (figure 1) that includes a tantalum disc and PTFE sealing gasket in addition to the former mentioned items. As mentioned before, cements are used in three-piece plug repairs to fill in the cavity of the damaged area and between the discs and the gaskets.

Figure 1

Patches

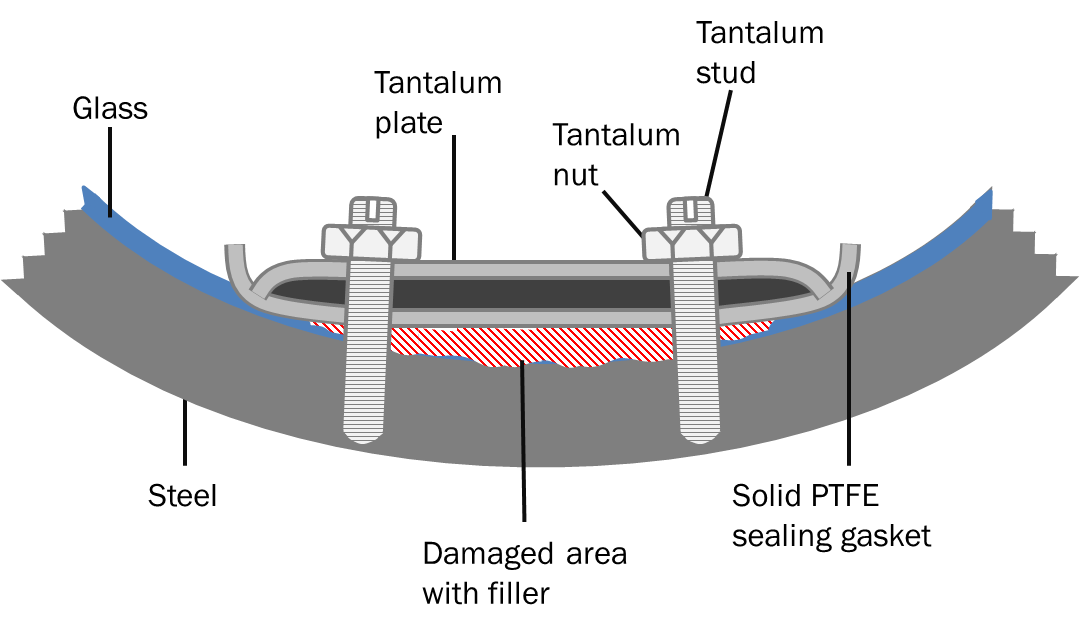

Patches become a necessary repair method when the size of the damaged area exceeds the coverage of plugs. Patches are most commonly made of tantalum and come in various shapes such as circles, squares or rectangles. Patches can be installed at the customer site in 1-2 days, minimizing downtime that is faced during more involved methods of repair like reglassing. Patches are comprised of a sheet of tantalum, tantalum studs and nuts, a sheet of PTFE, and repair cement (see figure 2).

Figure 2

Sleeves

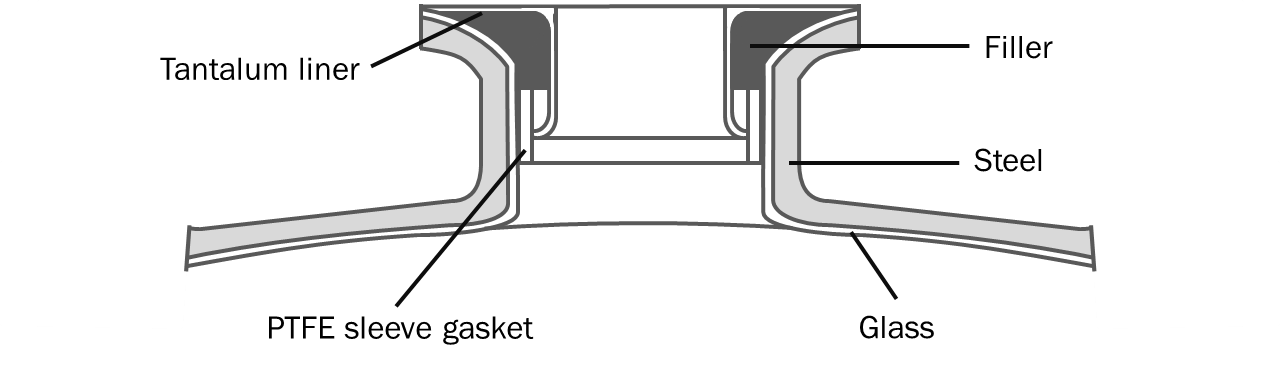

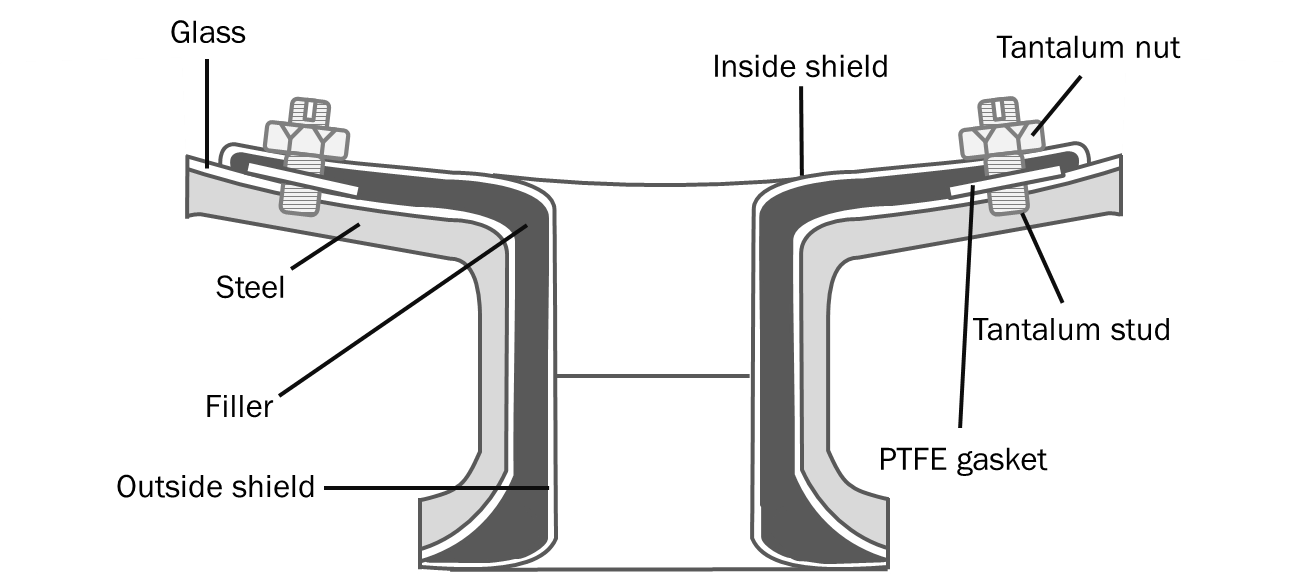

Metal sleeves are most commonly used to repair damaged nozzles; the inaccessibility of this space due to the compact design of this vessel component usually prevents the use of a plug or patch in these small areas. There are three types of sleeves available – inside, outside and inside-outside. After evaluating the location of the damage and supplying the precise measurement, a vendor can supply you with the type of sleeve that will be the best fit. As with other repair methods, tantalum is the metal most frequently used in sleeve repairs. PTFE gaskets and cement are also used in conjunction with the metal sleeve.

Outside (figure 3) and inside-outside sleeves (figures 4a and 4b) constructed of PTFE can also be used to cover minor damage to the inside of nozzles. In the instance of inside-outside models, no cement, studs or nuts are required so installation can be achieved in only a few hours. However, it should be taken into account that the nozzle diameter will decrease by about one inch when this device is used.

Figure 3

Figure 4a (bottom outlet)

Figure 4b (top nozzle)