Cleanability, Process and Maintenance Optimization on Glass-Lined Double Conical Dryers

Glass-lined double conical dryers are a workhorse in the pharmaceutical and fine chemical industries, with a rigorous design that enables them to run for decades. A common issue with these units, however, is the vessel's cleanability. Enhancements are available that provide revamping possibilities that will improve not only the cleanability and filtration process, but will also significantly reduce the maintenance cycle time. This blog post features a case study that illustrates how an upgrade to the dryer vacuum tube can accomplish all of these improvements.

Glass-lined double conical dryers are a workhorse in the pharmaceutical and fine chemical industries, with a rigorous design that enables them to run for decades. A common issue with these units, however, is the vessel's cleanability. Enhancements are available that provide revamping possibilities that will improve not only the cleanability and filtration process, but will also significantly reduce the maintenance cycle time. This blog post features a case study that illustrates how an upgrade to the dryer vacuum tube can accomplish all of these improvements.

Background

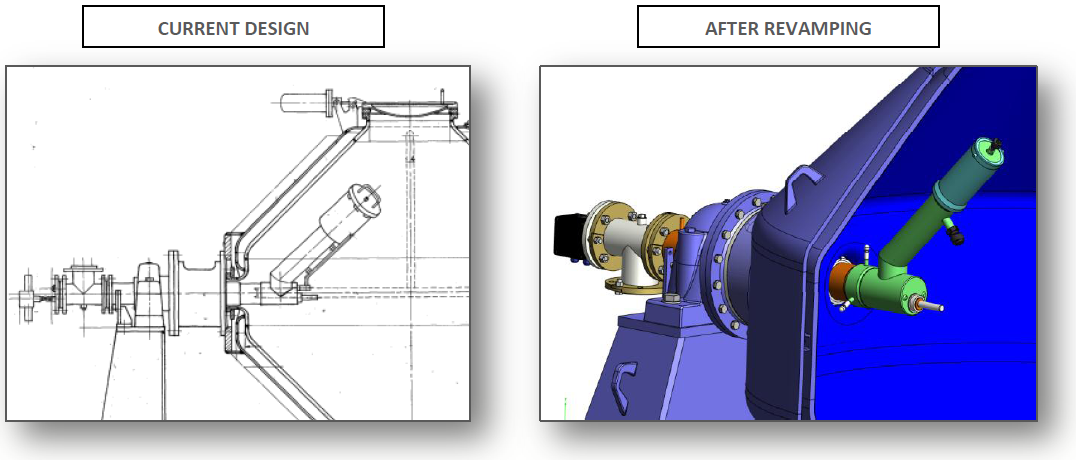

The double conical dryer that is the subject of this study was manufactured in 1992, and has been in service for more than 26 years. The customer had no CIP (Clean-In-Place) system inside the dryer and was manually cleaning the interior surfaces from the outside of the vessel. The revamped design was manufactured in alloy C22 (though other materials of construction are available depending on the specifications of your process).

CIP Study

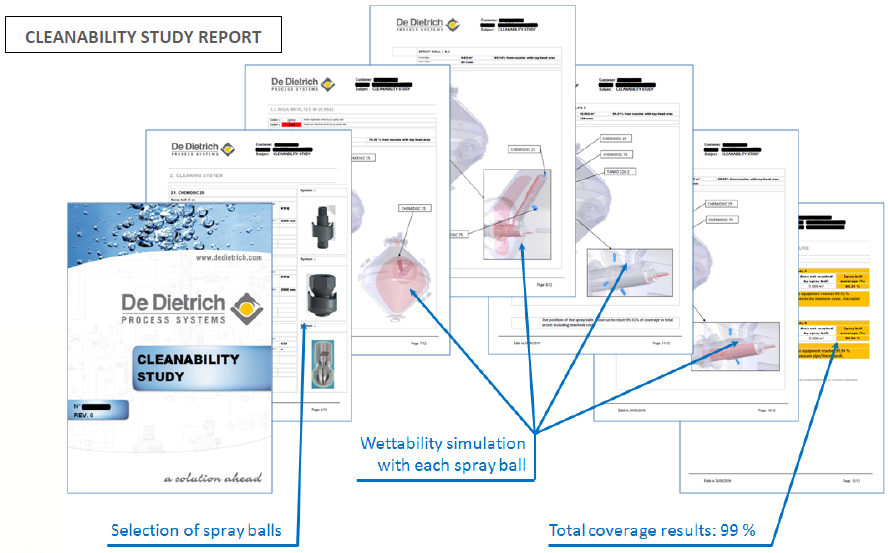

To identify the best solution, De Dietrich Process Systems' Engineering Department conducted a CIP study. This study was based on several steps:

- Selection of the type/model of spray balls to be used (material, speed, spraying range, etc.)

- Positioning of the spray balls inside the vessel to reach an optimal cleaning

- Simulation of the wettability using 3D software

The simulation that produced the best results achieved a total coverage of 99% wettability with five spray balls. (The wettability simulation takes only into account the direct jet impact of the spray balls; during the cleaning cycle, additional mist and run-off effects will further increase the cleanability.)

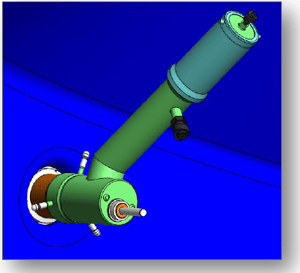

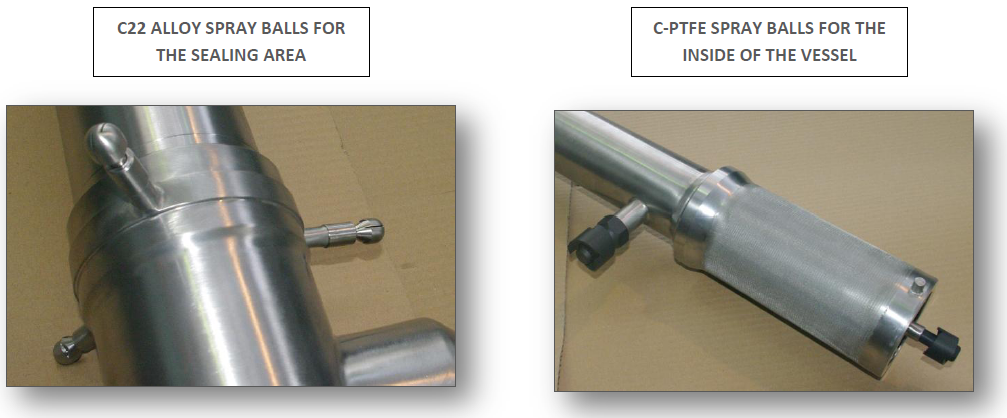

In addition to the wettability simulation, the testing conducted during the study helped to define an internal CIP solution. Five internal spray balls were added on the new vacuum tube to optimize the cleaning of the conical dryer. Of the five, three small rotational spray balls in C22 alloy are dedicated to clean the sealing area (an area which is always difficult to clean and often considered to be a critical dead zone). Two rotational spray balls in C-PTFE (graphite-loaded PTFE) were positioned to clean the inside of the vessel.

In addition to the wettability simulation, the testing conducted during the study helped to define an internal CIP solution. Five internal spray balls were added on the new vacuum tube to optimize the cleaning of the conical dryer. Of the five, three small rotational spray balls in C22 alloy are dedicated to clean the sealing area (an area which is always difficult to clean and often considered to be a critical dead zone). Two rotational spray balls in C-PTFE (graphite-loaded PTFE) were positioned to clean the inside of the vessel.

Vacuum Filtration Optimization

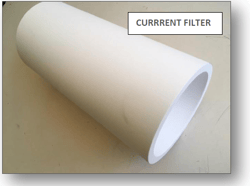

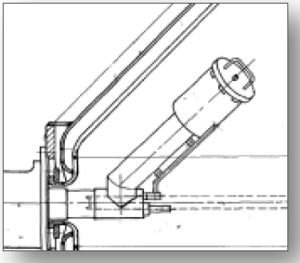

The existing filter design, shown in the image below/left, was constructed using a porous PTFE sleeve with pores that averaged 50 microns in diameter. While fine particles could pass through the filter (size below 5 to 10 microns), it was impossible to clean or unclog the filter.

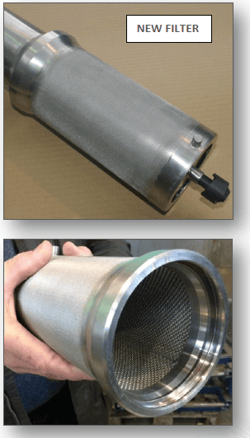

The updated filter features a filter mesh that is not only easy to clean and unclog but contains a more homogenous porosity with much smaller pore diameters (5 to 20 microns). The filter is constructed as a multi-layer grid welded by sinterization, making it much more durable than the previous version.

Lip Sleeve Part Replacement

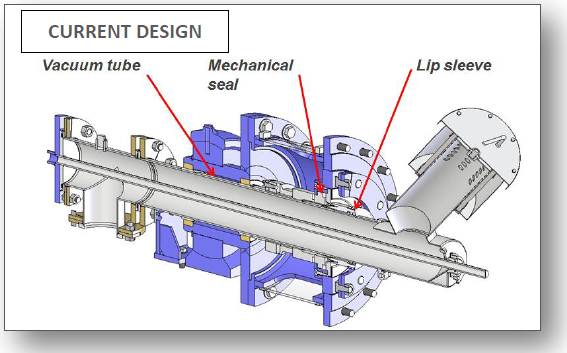

With the original design of the vacuum tube, three days of maintenance were required to completely remove the lip sleeve from the dryer. Changing this critical part required more than 12 different operations from both inside and outside the dryer. In fact, in order to access the lip sleeve for replacement or cleaning, the complete vacuum tube and the mechanical seal needed to be removed! As you can imagine, this was a time-consuming hassle that created an excessive amount of downtime.

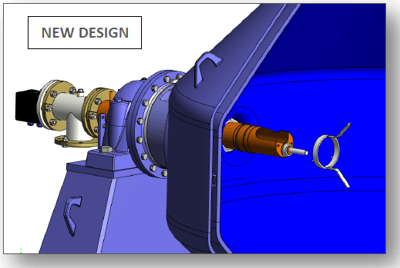

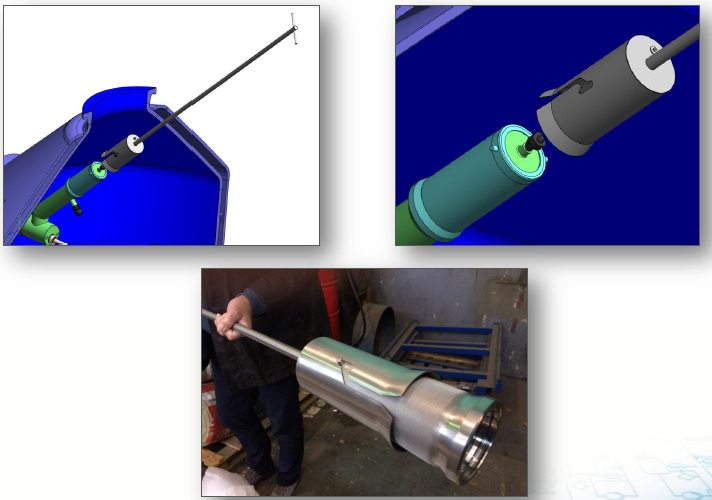

The revamped vacuum tube design (see image below) significantly reduces maintenance time to half a day, with a maximum of 5 operations. The lip sleeve can now be easily removed from the vessel using a special key tool (see below in green) and without the need to fully remove the vacuum tube or mechanical seal.

A maintenance nut was also added to facilitate the dismantling and extend the lifetime of this part.

A maintenance nut was also added to facilitate the dismantling and extend the lifetime of this part.

Filter Dismantling Maintenance

There were several disadvantages to using the existing filter design. Removal and replacement of the filter was a lengthy, manual process. Additionally, the filter and holding cage were relatively heavy (approx. 10 lbs.), making it difficult to handle inside the vessel - accidentally dropping the part inside the vessel could damage the enamel.

There were several disadvantages to using the existing filter design. Removal and replacement of the filter was a lengthy, manual process. Additionally, the filter and holding cage were relatively heavy (approx. 10 lbs.), making it difficult to handle inside the vessel - accidentally dropping the part inside the vessel could damage the enamel.

These constraints were taken into account when designing the new filter for dismantling/ maintenance. The revamped filter weighs only about 2 lbs. and can now be easily and directly removed from the outside without entering the vessel. A unique, bell-shaped tool was created to enable easy dismantling.

Results

The upgraded filter design in the glass-lined double conical dryer has resulted in numerous advantages, including:

- Optimized cleanability: The wettability simulation assessed various solutions, and the CIP study was critical in identifying dead zones and selecting the optimal solution to achieve the most thorough cleaning possible.

- Significantly reduced cleaning cycle time: With considerably less time needed to perform standard maintenance procedures, more time can be spent with the machine in production mode.

- Improved filtration process: The easy-to-clean, thinner filter mesh is more durable, and the uniform porosity improves filtration efficiency and eliminates clogging.

- Reduced maintenance cycle time: With maintenance procedures drastically simplified, maintenance operations can be performed more quickly and easily.

- Improved operator safety: Filter cleaning and replacement can be done outside the vessel, saving time while reducing the number of procedures that require maintenance personnel to work inside the vessel.

De Dietrich Process Systems manufactures glass-lined steel conical dryers that effectively combine the drying and mixing function in one simple and stable device. The rotation of the double cone allows the product to be mixed and dried without an internal agitator, make it suitable to processing easily flowing, corrosive products for drying, mixing or concentrating pharmaceuticals, dyes, pigments, synthetic resins, and other materials. For more information about these units and our other drying equipment visit the Dryers section of our website, or download a free copy of our white paper detailing Guidelines on Specifying an Indirect Dryer. If you are looking to revamp your existing dryer design have any other questions contact us online or at 908-317-3585.