The Benefits of Vision Systems for Filter-Dryers

Anyone familiar with nutsche filtration and drying knows that every step in the batch process must be carefully timed to achieve consistent, high-quality results.

Constructed mainly of stainless steel or Hastelloy, filter-dryers are impressive pieces of equipment but don’t typically offer a great view into what’s going on in the vessel interior at any given time. This lack of visibility can limit process control and efficiency. To overcome this, vision systems for filter- dryers provide a simple but powerful solution. These systems enable real-time monitoring and automation, leading to safer operation, shorter cycle times, and more consistent product quality.

In this article, we’ll explore the key benefits of installing a vision system on your filter-dryer, and why it's a smart investment for process optimization.

What Is a Vision System for Filter-Dryers?

A vision system is designed to allow remote viewing and monitoring of what’s happening inside a vessel during operation. While this may seem straightforward, the ability to observe internal process changes in real-time can dramatically improve batch control, efficiency, and product quality.

Below are the key advantages of integrating a vision system with your filter-dryer.

Benefits of Vision Systems

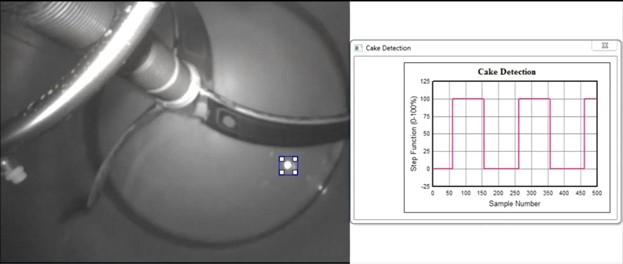

1. Real Time Level Measurement and Cake Detection

Many processes have very specific standards that must be obtained to uphold the integrity of the product; any miscalculation can cause a delay in the process.

A vision system allows operators to monitor the cake level as it forms in real time. This ensures process steps are triggered at the optimal time, reducing idle time and preventing over-processing or delays due to miscalculations.

2. Non-Contact Level Control

Being able to monitor the vessel contents remotely can eliminate product contamination as well as operator exposure.

It can also help to prevent the overfilling of the filter while charging slurry or wash liquid into the vessel. This can also be integrated through the use of automated valves to automate the feed and wash operations of the filter/dryer, allowing for completely automated process control.

3. Avoid Cracking Cake Layer

Cake cracking is a common issue that can compromise washing steps and lead to product loss. Vision systems provide the ability to see the cake as soon as it is formed before blow-through is achieved. Careful visual monitoring is a key step to preventing a cake from cracking, allowing for subsequent washes to be performed without manual smoothing of the cake. This ensures that your washing steps are efficient.

4. Stop Washing Product Away

When the cake layer remains intact, there is less risk of washing away fines or valuable product, especially in pharmaceutical or high-purity applications.

By avoiding cake cracks and reducing manual interventions, the cycle time can be greatly reduced leading to higher throughput and lower operational costs.

5. Visual Verification

With a vision system, you can watch the process remotely from the safety of a control room or other remote location. This includes:

- Monitoring for issues like balling, blinding, or cake cracking

- Measuring cake height visually

- Identifying mechanical or maintenance concerns as they arise

This level of insight reduces downtime and helps maintain consistent performance.

Versatility Across Process Units

The combination of these benefits presents a unique opportunity to increase the efficiency of any nutsche filtration and washing process. The system can be calibrated and implemented regardless of vessel size and is flexible enough to meet the specific demands of your process unit operations.

Integrating Vision Systems with your Equipment

Vision systems are simple to integrate with new or existing equipment. Typically, they include an integrated light and can be easily mounted to an existing nozzle or can replace the existing vessel light assembly.

Based on the benefits listed above, it’s easy to see how a vision system can pay for itself in the optimization it offers to your process.

At De Dietrich, we offer vision systems as a standard feature on all new nutsche filter-dryers. We also supply retrofit kits to upgrade filter-dryers already installed at your facility.

To learn more about integrating a vision system with your filter-dryer, or to request a quote, contact us today. Our team can help assess your setup and provide a customized solution for your application.