The Safety Edge: Why Nutsche Filters Are the Safer Choice in Filtration Technology

Filtration is a critical process in various industries, from pharmaceuticals to chemical manufacturing. The choice of filtration equipment can significantly impact not only the efficiency and quality of the outcome but also the safety of the operation. Among the different filtration methods available, Nutsche filters have emerged as a standout option for ensuring safer operations. This post delves into the safety benefits of Nutsche filters compared to other filtration methods.

Filtration is a critical process in various industries, from pharmaceuticals to chemical manufacturing. The choice of filtration equipment can significantly impact not only the efficiency and quality of the outcome but also the safety of the operation. Among the different filtration methods available, Nutsche filters have emerged as a standout option for ensuring safer operations. This post delves into the safety benefits of Nutsche filters compared to other filtration methods.

What are Nutsche Filters?

Nutsche filters are a type of filtration equipment used for solid-liquid separation. They combine filtration with drying capabilities, making them particularly useful in industries where both processes are integral. The design of Nutsche filters allows for operations under vacuum or pressure conditions, catering to a wide range of substances and operating parameters.

Safety Benefits of Nutsche Filters

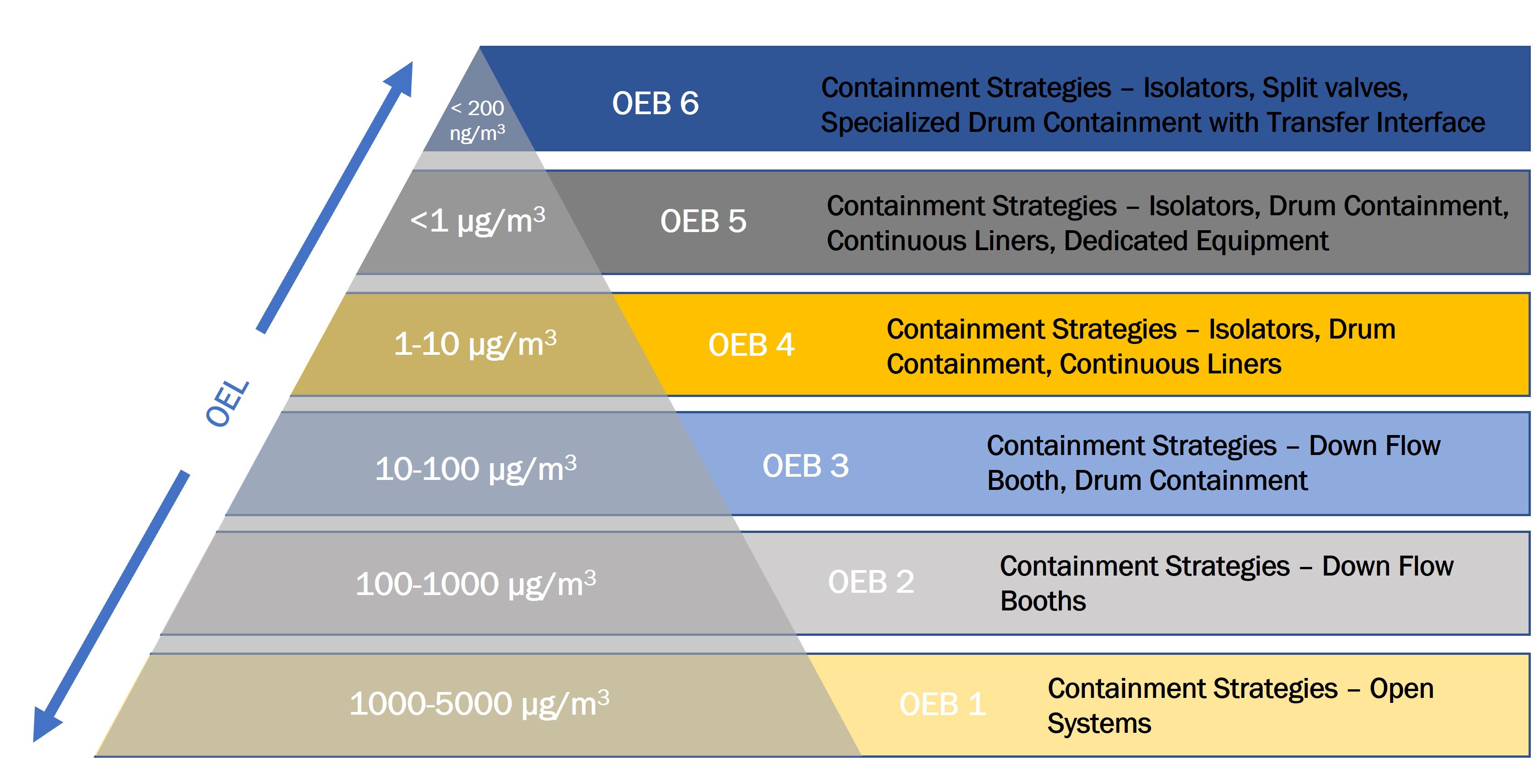

Nutsche filters offer numerous safety benefits over other filtration methods, including:- Controlled Environment: Nutsche filters operate as a closed system, which minimizes the exposure of operators to harmful substances, and allows for inert operation as needed. With regard to toxic materials, a full spectrum of Occupational Exposure Band (OEB) requirements can be met through a combination of filter design, auxiliary isolators, pack-off stations, and customer best practices. For flammable processes, a closed system can be rendered inert with the proper gas supply and safety sequencing. This closed system design is crucial for reducing the risk of exposure to personnel, contamination of the product, and solvent-based processing.

- Pressure and Vacuum Operations: The ability to operate under pressure or vacuum conditions not only enhances efficiency but also ensures safety. Vacuum conditions, in particular, reduce the chances of volatile reactions occurring in oxygen rich environments, which is a significant safety advantage when dealing with reactive substances.

Temperature Control: Nutsche filters provide excellent temperature control during the filtration and drying phases. Features such as a full encompassing jacket on the vessel side walls, along with heat transfer through the the bottom plate or even the agitator contribute to efficient and precise temperature control. This controlled environment prevents overheating and potential thermal hazards, ensuring a safer operation.

Temperature Control: Nutsche filters provide excellent temperature control during the filtration and drying phases. Features such as a full encompassing jacket on the vessel side walls, along with heat transfer through the the bottom plate or even the agitator contribute to efficient and precise temperature control. This controlled environment prevents overheating and potential thermal hazards, ensuring a safer operation.- Automation and Monitoring: Many Nutsche filters come equipped with automated features and process monitoring systems through advanced controls systems and safety interlocks. This reduces the need for manual intervention and allows for safer, more precise control of the filtration process.

- Reduced Handling: Since Nutsche filters combine filtration and drying in a single unit, the need for transferring materials between different equipment is minimized. This reduction in handling lowers the risk of spills, exposure, or accidents, and can reduce losses due to excessive product handling.

Comparison with Other Filtration Methods

Traditional filtration methods like rotary drum, belt filters, or centrifuges often involve more open or semi-open systems, which can increase the risk of exposure to hazardous materials. Moving parts found on these technologies also increase the chance of physical risk to operators such as pinch points and crushing injuries. Nutsche filters have fewer exposed moving parts for standard operation, making them inherently safer by design.

Nutsche filters' enclosed system is a significant safety advantage over these traditional methods, especially in terms of containing toxic fumes and preventing contamination to the product or operations area. The integrated drying function of Nutsche filters also reduces the need for additional handling and transfer of materials, which can be a point of risk in other methods such as cone, tray, or rotary dryers.

In the world of industrial filtration, safety is paramount. Nutsche filters offer a combination of features that enhance safety significantly over other filtration methods. Their controlled environment, ability to operate under varying pressures, and reduced handling requirements make them a superior choice for industries prioritizing safety alongside efficiency and effectiveness. Contact us if you'd like to speak with one of our filtration experts and get more information on how Nutsche filtration might be a good fit for your process.