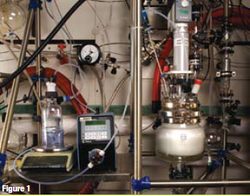

Chemical Development has 29 jacketed lab reactors, all supplied by De Dietrich Process Systems, Inc. (De Dietrich calls them Miniplant reactors). GSK also uses De Dietrich pilot-scale reactors in its pilot plant operations in Philadelphia. Using equipment from the same manufacturer at both the development and pilot stages makes for a smooth transition in the scale-up of a process, says Flanagan. "Our lab reactors are scaled down versions of our pilot plant vessels," he says, "just as our pilot plants are scaled-down versions of production equipment." The 29 jacketed lab reactors at RTP consist of 13 1–6L, six paired 20 L kits and two paired 50 L kits. The smaller reactors are made of durable borosilicate glass and most are elliptical in shape, rather than round-bottomed, so their mixing characteristics are similar to those of a typical production-size reactor. A couple of conical-shaped vessels have also been installed for specialized studies. The 50 L kits are made of glass-lined steel and Hastelloy, identical to those found in pilot plants. The head of each lab reactor has a large central port for the agitator motor, which has either a single or double mechanical seal to ensure that the vessel contents are not compromised during operation. Other ports are available for purposes, including the addition of reactants and materials, a glass riser for distillation overhead, a thermowell for temperature measurements and other PAT functions.

In the glassware above the reactor is a manual valve that allows either reflux or removal of distillate. Each of the small reactors has a graduated receiver for distillate, but each pair of 20 L and 50 L vessels shares a single condenser and set of valves that allow distillate to flow from one vessel to the other. "This gives us the flexibility to reflux or distill from either vessel throughout the entire process," says Flanagan. "There is also a phase separator between them, so we can perform an azeotropic removal of water and direct either phase to either vessel." Product is removed through a valve at the bottom of the vessel — a manual valve on the smaller reactors and a pneumatically operated valve on the 20 and 50 L units. The design of the valve minimizes dead space and makes for a free flow of product through the valve, so that the product can be completely evacuated.

Work on new drugs starts in RTP's Drug Discovery Department, where potential drug candidates are made in quantities of up to a few grams in standard glassware. Those that show promise are moved on to Chemical Development, where processes to make active ingredients are scaled-up to produce quantities up to 100 grams in 1 or 2 L jacketed lab reactors. It is at this scale that most of the process development is done and basic problems are solved. "In these smaller reactors, we devote almost 100% of the work to process development and very little to making material to support studies," Flanagan says. "When we scale up to the 6 L and 20 L reactors, we are probably down to 30% development, and when we get to the 50 L scale, 90% of the work is for the production of material for testing … and we are just tweaking the process." The use of jacketed lab reactors has also enabled GSK to develop GMP (Good Manufacturing Practice), clean-in-place and cleaning verification procedures as a process is scaled up. In addition, the company has performed equipment qualification exercises on all the lab reactors that are used for clinical material preparations.