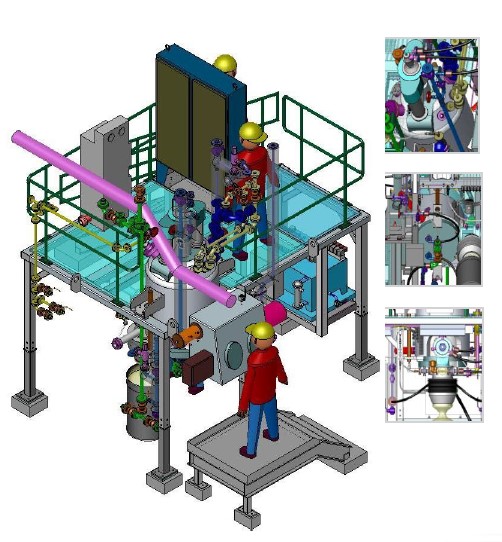

De Dietrich Process Systems proposed to provide each filter/dryer as a pre-assembled skid. The skids would be designed with process and service pipework connections conveniently located at the edge of the skid, enabling simple installation with three easy steps: the unit could simply be dropped into place, bolted to the floor, connections made, and it would be ready to run.

For the four identical modules the scope of supply was:

- Filter/Dryer with glove box for contained heel discharge and solids sampling

- Hydraulic power pack

- PLC control system with multiple panels for machine operation

- All local process and service piping, valves and instruments

- Support platform with lighting on the lower level for operator visibility

- Electrical pre-wiring to junction boxes

- Platform with support legs and access stairway

- Validation documentation

DDPS engaged in a design approach with the client that satisfied both operational and maintenance requirements. From an operational perspective, the design met the clients need to have extensive process and service valves in reachable locations. The assembly also gave unobstructed access to key areas to enable future maintenance activities that will arise during the module’s life cycle, such as mechanical seal PM and dust filter replacement.

The complete design was undertaken in 3D, with regular reviews conducted with the client team, including representatives of all interested departments from operations and maintenance to process engineering and validation. Before shipment to the client's site, the complete modules were assembled in the factory and subjected to rigorous testing.