Contained Transfer of Solids to and from Drums

-6-1.jpg?width=302&height=379&name=FLYER%20CSV%20DIT%20(1)-6-1.jpg) Many manufacturing processes involve the use of solid materials (e.g., powders, prills, and flakes) that are delivered in drums, or need to be charged into them. The drums themselves are typically made of either steel, plastic or fiberboard and have a variety of diameters and volumes. Also, depending on the solid material’s required purity, possible dangers to the environment or known toxicity to operators, it might (or might not) be contained within one or more secondary sealed bag(s) inside the drum.

Many manufacturing processes involve the use of solid materials (e.g., powders, prills, and flakes) that are delivered in drums, or need to be charged into them. The drums themselves are typically made of either steel, plastic or fiberboard and have a variety of diameters and volumes. Also, depending on the solid material’s required purity, possible dangers to the environment or known toxicity to operators, it might (or might not) be contained within one or more secondary sealed bag(s) inside the drum.

Given the variety of factors involved, it is easy to understand how and why the technique and equipment used to transfer solids into or out of drums, and contain them within a specific level can vary so much. The purpose of this blog post is to introduce the various levels of containment that have been established within the pharmaceutical and chemical industries and present some of the equipment options commonly used to transfer materials into or out of drums and maintain a specific level of containment.

Material Containment Levels

There are two (2) primary designations when categorizing containment levels required for most materials.

- Occupational Exposure Limit (OEL)

- Occupational Exposure Band (OEB)

In general, the Occupational Exposure Limit (OEL) provides a specific level of admissible exposure (usually over 8 hours) to a specific chemical or material such that it is unlikely to affect the health of a worker. OEL is typically measured in (mg/m3) for solids and parts per million (ppm) for vapors and gases that are at normal room temperature and pressure.

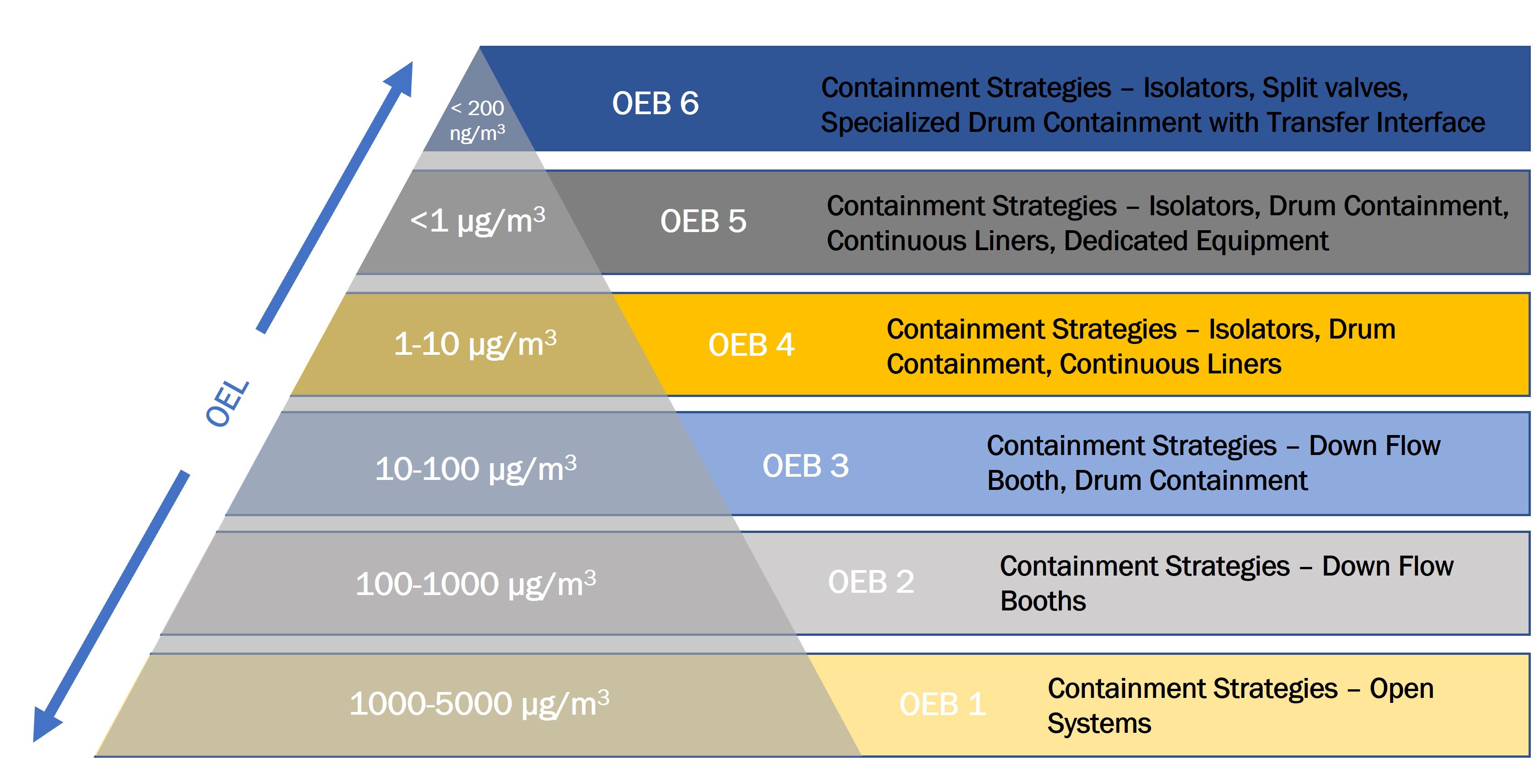

Occupational Exposure Bands (OEB) are a more general method of describing the exposure limits established for Active Pharmaceutical Ingredients (APIs) or other potent compounds and materials that typically do not have an established OEL. There are six bands associated with this classification system, and each has an OEL range associated with it. Oftentimes, this chart is also used by companies to categorize types of containment or personal protective equipment recommended to limit exposure to the range of each band.

The following chart lists the OEL ranges associated with each OEB and provides general descriptions of some containment methodologies that are used, but are not necessarily the only ones available to achieve the OEL range listed.

OEL/OEB Containment Table

OEB Level 1: (1000-5000 μg/m3)

This is the lowest level of containment required and is acceptable when the material does not pose any threat to worker safety. The only containment control method typically required is local ventilation of the room. Drum covers may be opened and removed, and the material can be transferred by manually scooping, vacuuming with a lance or even pouring the solids out of an inverted drum with no other protective measures being employed. However, it is always a good practice for operators to wear at least an N95 rated dust mask when handling solids to prevent inhaling an excessive number of airborne particles.

OEB Level 2: (100-1000 μg/m3)

At this level, there is minor risk to the health of the worker due to the toxicity of the material. As such, pragmatic steps should be taken to reduce operator exposure, and in most cases a local air extraction hood with a dedicated ventilation system will provide sufficient protection. Alternatively, drums can be opened, and material charged or removed while it is within a downflow or crossflow booth with a dedicated ventilation system. Again, it remains a good practice for operators to wear at least an N95-rated dust mask when handling open drums of solid material.

At this level, there is minor risk to the health of the worker due to the toxicity of the material. As such, pragmatic steps should be taken to reduce operator exposure, and in most cases a local air extraction hood with a dedicated ventilation system will provide sufficient protection. Alternatively, drums can be opened, and material charged or removed while it is within a downflow or crossflow booth with a dedicated ventilation system. Again, it remains a good practice for operators to wear at least an N95-rated dust mask when handling open drums of solid material.

OEB Level 3: (10-100 μg/m3)

Materials at this level are potentially hazardous to the safety of workers. Flexible isolators, glove bags and continuous liner systems are commonly used to provide a suitably protective containment barrier while removing material from a drum.

Flexible Enclosure with Glove Ports & Continuous Liner

OEB Level 4: (1-10 μg/m3)

Materials in this category are deemed hazardous, so significant measures must be taken to prevent operator exposure. Physical barriers should be always in place between the operator and the material. Rigid wall isolators which allow an operator to handle the material inside the enclosure through externally accessed glove ports are commonly used.

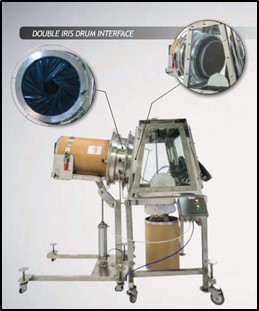

Drum Iris Technology, Rigid Enclosure with Glove Ports & Continuous Liner with Inflatable Seal

OEB Level 5: (< 1μg/m3)

At this level, the material is highly hazardous so significant measures must be taken to prevent operator exposure. There should be a permanent physical barrier between the operator and the material. Closed material handling and transfer is routinely done inside isolators via glove ports.

Double Drum Iris Technology, Rigid Enclosure with Glove Ports, A/B Split Valves, Bag in / Bag out HEPA Filters

OEB Level 6: (< 200 ng/m3)

Material containment at this level is reserved for the most hazardous biological materials and is typically beyond the scope of equipment that is normally provided to control material exposure when removing or charging to or from drums.

De Dietrich can provide systems designed, tested and proven to meet nearly any required OEB / OEL containment level when filling or emptying solids into or out of drums. We specialize in every level down to OEB 5 and can meet 1 ug/m3. Contact us for more information about our drum containment solutions.