Handling Hazardous Bulk Solids and Powders: Safety First!

In numerous industries, the movement and storage of bulk solids and powders are standard operations. However, when these materials are hazardous, the stakes become considerably higher. The mishandling of hazardous bulk materials can lead to catastrophic results, including explosions, toxic releases, and environmental damage. In this blog post, we'll dive into the best practices for handling hazardous bulk solids and powders, ensuring safety for both personnel and facilities.

Recognizing the Hazards

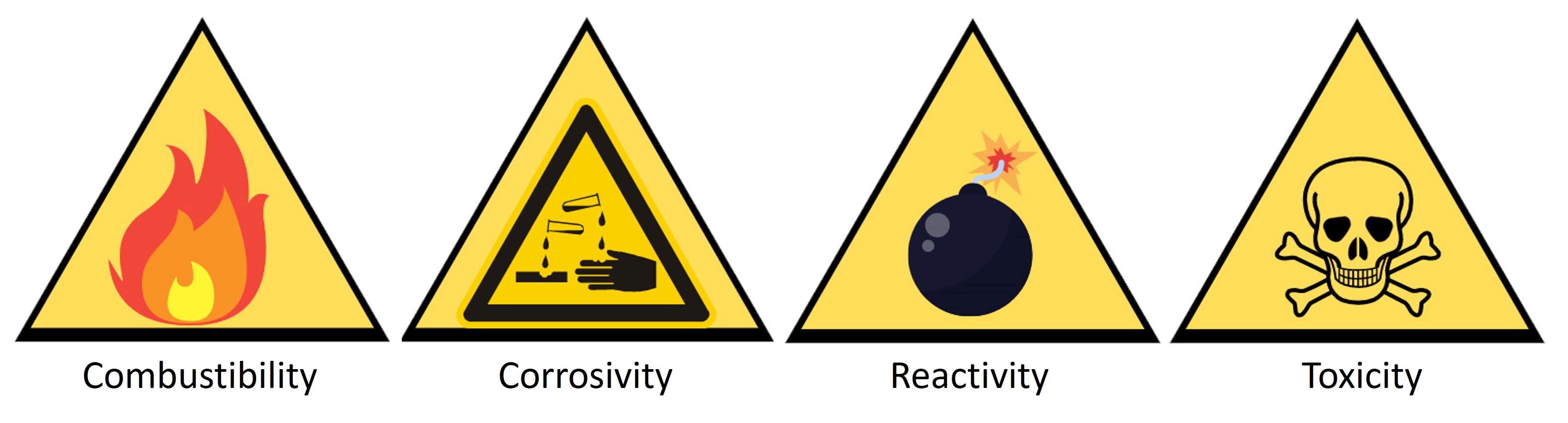

Before diving into safety protocols, it's essential to understand the risks associated with certain bulk solids and powders:

- Combustibility: Many powders, when suspended in air, can create explosive dust clouds. Examples include flour, sugar, and metal powders.

- Corrosivity: Chemical powders that are basic or acidic in nature can attack and destroy metal and other fabrication materials used in conveying equipment. Examples of this can include the powder, granular, crystalline or flake form of compounds such as sodium hydroxide and acid salts.

- Reactivity: Some materials can react violently with other substances or even with air or water. For example, certain metal powders can ignite upon exposure to moisture.

- Toxicity: Some powders can be harmful or fatal if inhaled, ingested, or even upon skin contact.

Safety Measures for Handling Hazardous Bulk Solids & Powders

Following these general guidelines will ensure you are taking into account all the major safety aspects and best practices to keep your system and personnel from potential danger:- Comprehensive Training: All personnel should undergo regular training, ensuring they're aware of the risks associated with the materials they handle and the safety measures to mitigate these risks.

- Ventilation and Dust Control: Proper ventilation systems, combined with dust collection and suppression mechanisms, can significantly reduce the risk of dust explosions and worker exposure.

- Static Control: Static electricity can ignite a dust cloud. Ensure that equipment is grounded and consider using anti-static materials and tools.

- Regular Maintenance and Cleaning: Regularly inspect and maintain equipment. Avoid letting dust accumulate, as even a thin layer of dust can become airborne and create an explosive atmosphere.

- Safe Storage: Store hazardous materials in well-labeled, sealed containers, preferably in designated areas. Understand the material's properties – some might require cool, dry environments, while others might need inert atmospheres.

- Explosion Protection: Install safety devices like explosion vents, suppression systems, and flame arrestors in areas where dust explosions are a potential risk.

- Personal Protective Equipment (PPE): Ensure workers have access to and use the necessary PPE, such as respirators, gloves, and protective eyewear.

- Safety Data Sheets (SDS): Always have an up-to-date SDS for every hazardous material in the facility. The SDS provides vital information about the material's properties, potential hazards, and emergency response measures.

- Emergency Protocols: Develop and regularly review emergency response protocols. This includes evacuation plans, first-aid measures, and emergency contact numbers.

- Eliminate Ignition Sources: Keep potential ignition sources away from areas where hazardous powders are handled or stored. This includes open flames, sparks, and hot surfaces.

Advanced Technologies for Safe Handling

Additional safe handling measures can be taken using advanced technologies involving inertion and/or monitoring. By replacing the atmospheric air in a system with an inert gas like nitrogen, you can reduce the risk of combustion through the creation of an inert environment within the closed system. With regards to monitoring systems, modern sensors can be integrated to detect changes in temperature, pressure, or gas concentrations, providing early warning signs of potential issues.

Handling hazardous bulk solids and powders requires vigilance, knowledge, and a commitment to safety at all levels of operation. By understanding the risks and implementing stringent safety protocols, industries can ensure that they move and store these materials without compromising the safety of their workers, their facility, or the environment. Remember, with hazardous materials, always err on the side of caution!

Operator safety is a critical component to all De Dietrich solids handling solutions. Our Powder Pump, in conjunction with other components, can provide safe, reliable transfer utilizing dense phase pneumatic conveying. For more information about how you can safely transfer your material (hazardous or not), read our white paper on Safely Charging Solids into Process Reactors.