Guide to Agitated Nutsche Filter-Dryer

The agitated nutsche filter-dryer is a versatile, multipurpose piece of equipment used in a wide range of industrial processes. Often located just downstream of a reactor or crystallizer, it plays a critical role in separating and isolating solids from a solvent. It has certainly come a long way since its beginning, when the nutsche filter design consisted of an open vessel that simply used suction to achieve separation.

The agitated nutsche filter-dryer is a versatile, multipurpose piece of equipment used in a wide range of industrial processes. Often located just downstream of a reactor or crystallizer, it plays a critical role in separating and isolating solids from a solvent. It has certainly come a long way since its beginning, when the nutsche filter design consisted of an open vessel that simply used suction to achieve separation.

Modernization led by Rosenmund in the 1960’s enclosed the vessel for containment, enabling the introduction of pressure and agitation. The closed system further allowed for process control over parameters like temperature, pressure, pH, and agitation. In addition to expanding the unit’s operations, containment protects operators and isolates the product from the atmosphere.

While the agitated nutsche filter-dryer maintains its original process functionality, technological in recent decades have made it a critical component in contained, batch processes for final and intermediate product isolation. Specialty batch-oriented applications like pharmaceutical and fine chemical production, dye, paint, and wastewater treatment commonly utilize agitated nutsche filter-dryers. This is because nutsche filter-dryers are suited to handle even the most hazardous products (flammable, toxic, corrosive, etc.).

Nutsche filter-dryers are very flexible from a process standpoint; while they are typically used to reclaim solid products, there are rare instances when the solution is the desired end product (e.g. catalyst recovery, extraction, etc.). The modern day nutsche filter can perform a multitude of tasks including filling/charging, filtering, displacement washing, reslurry washing, smoothing, drying/cooling, and discharging. Combining the various filtration and drying steps in the same unit is a desirable function, especially for processing active pharmaceutical ingredients (APIs) and hazardous chemical compounds such as pesticides.

Nutsche Filter Configuration

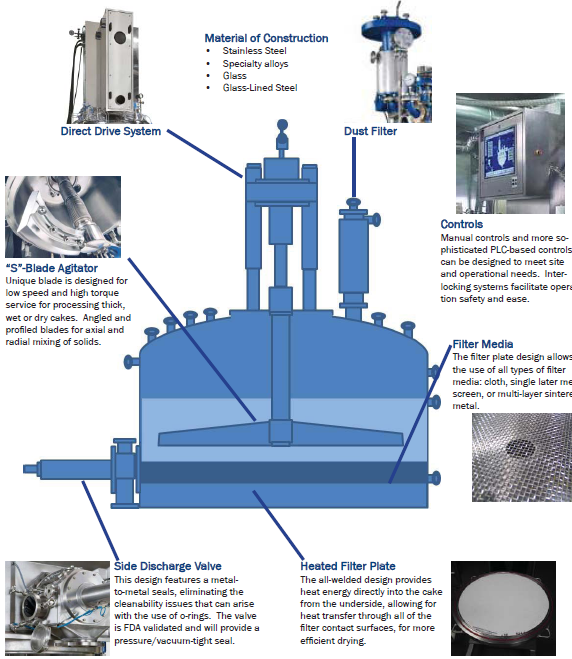

The nutsche filter-dryer is comprised of four key components:

- Vessel – This is the main body of the unit and may come in either a one-piece or two-piece construction, with several base designs available. Vessels can be jacketed for temperature sensitive applications in order to provide effective heat transfer to the product. Insulation and sheathing, main body flanges, and pusher ports are also optional features.

- Drive assembly – The agitator mechanism includes an S-blade agitator, twin- or quad-column support structure, bellows, gear box, shaft coupling, and double dry mechanical seal.

- Discharge valve – This side-mounted valve has a fail-safe metal-to-metal seal with pressure capabilities, hinge, monorail, and hydraulic actuation. It reliably handles the automatic discharge of solids or liquids, including dry product, slurry, or wet cake.

- Dust filter – Flange-mounted to the top of the vessel, the dust filter can accommodate various types of filter media and comes fully jacketed with insulation and sheathing in a pressure rated housing to safely and effectively eliminate dust blowback. It also includes a nitrogen accumulation tank for contained element removal.

Construction

Due to the nature of the processes that are typically performed (i.e. highly toxic, require containment), nutsche filter-dryers are usually constructed of either stainless steel, specialty alloys or glass-lined steel. They are also available in borosilicate glass 3.3 for applications where chemical inertness and visibility are important. Additional modifications can be made to the design to accommodate cGMP, CIP, aseptic, and sterile requirements. Since the nutsche filter-dryer is a batch system, it must be sized according to your upstream equipment capacity.

While there are some smaller-scale manually operated nutsche filter-dryers available (see more information on our Roman Filter, for example), most units are automated and use a combination of electric, pneumatic, and hydraulic systems for actuation. The operational sequence of full production-sized machines involves a complex series of discharge valve and agitator system manipulations, so most units are semi or fully automated.

The three main types of filter media that are used to cover the filter plate are woven metallic mesh screen, synthetic filter cloth, and sintered metallic plate. The material is selected based on the characteristics of the solids, the liquid, and the vessel material of construction. If unsure, pilot testing is the best way to determine medium selection.

Nutsche Filter-Dryer Applications

Not every separation process requires the level of technology provided by a nutsche. Nutsche filter-dryers are best selected for applications with the following process requirements:

- Minimum floor space

- Risk of environmental hazard from toxic or flammable products

- Precise temperature control

- Reslurry washing

- Absolute separation between the mother liquor and wash solutions

- Delicate cakes (i.e. tend to crack easily)

As with all specialized equipment, nutsche filter-dryers are not intended to be a solution for all separation processes. They should be selected with care. In instances where cakes are slow to form or are sticky, if the process is continuous, or if the product deteriorates during a long period of downtime the technology may not be an appropriate solution.

Multipurpose Agitator

The S-blade agitator is a unique feature of the agitated nutsche filter-dryer and helps not only with mixing but reslurry, cake formation, drying, and product discharge. When the agitator is run in reversed rotation (counterclockwise), it exerts controlled pressure on the surface of the cake, effectively sealing cracks and maintaining a uniform cake so that air or gas does not bypass the filtration bed.

To further reduce cake moisture, the heated agitator can be slowly rotated and lowered to scrape and de-lump the cake while providing an additional source of heat to enhance drying. Whether using conductive vacuum or convective pressure drying, you can accomplish drying with less than < 0.1% final product moisture possible. This video demonstrates how the agitator facilitates drying:

The agitator also serves as the primary mechanism for product discharge. When rotated clockwise, it pushes the dry cake towards the vessel wall during each rotation, thus expelling product intermittently out through the side discharge valve.

Why Choose an Agitated Nutsche Filter-Dryer?

Agitated nutsche filter-dryers can effectively perform the separation of solid matter from a liquid under pressure or vacuum, in a closed system. The ability to isolate the product not only reduces product handling but also minimizes operator exposure and serves as environmental protection against solvent vaporization. Additionally, if you are in the pharmaceutical field or other industry where containment is critical, the high level of containment maintained can comply with GMP and other health and safety requirements (< 1µg/m³ on 8 Hr TWA).

De Dietrich offers nutsche filter-dryers from laboratory to production scale with different materials of constructions and features to meet the requirements of your product. For a complimentary assessment, fill out our Filtration Questionnaire and give us the details of your process or contact us so we can help identify a solution for your filtration and drying needs.

Frequently Asked Questions

What is an Agitated Nutsche Filter-Dryer used for?

An Agitated Nutsche Filter-Dryer is used for solid-liquid separation under vacuum or pressure in a closed system. It is ideal for processing hazardous, flammable, or sensitive compounds in industries like pharmaceuticals, chemicals, dyes, and wastewater treatment.

What makes an Agitated Nutsche Filter-Dryer different from other filtration systems?

Unlike standard filtration systems, a Nutsche Filter-Dryer combines multiple steps—filtration, washing, drying, and discharge—in one sealed vessel. This reduces handling, improves containment, and enhances drying efficiency.

Can Nutsche Filter-Dryers handle toxic or flammable materials?

Yes. These units are specifically designed for processing toxic, flammable, or corrosive substances. Their enclosed design minimizes operator exposure and solvent vaporization, helping you meet strict safety and GMP standards.

What types of filter media are used in a Nutsche Filter-Dryer?

Common filter media include woven metal mesh screens, synthetic filter cloth, and sintered metal plates. The choice depends on the slurry characteristics and the vessel’s construction material.

What is the typical moisture level after drying with a Nutsche Filter-Dryer?

With vacuum or convection drying, final product moisture levels can be reduced to less than 0.1%, making these systems suitable for moisture-sensitive compounds and fine powders.