Solids Flow Issues - Causes and Cures

Over the past 50+ years, the flow of solids from hoppers, bins and silos has been studied extensively and is well documented. There are several properties that affect how a particular solid will flow. These can be measured, and with this knowledge, containers can be properly designed to promote uninterrupted solids flow and avoid problems such as arching (bridging), rat-holing and funnel flow.

Over the past 50+ years, the flow of solids from hoppers, bins and silos has been studied extensively and is well documented. There are several properties that affect how a particular solid will flow. These can be measured, and with this knowledge, containers can be properly designed to promote uninterrupted solids flow and avoid problems such as arching (bridging), rat-holing and funnel flow.

This article provides an overview of some of the key properties of solids, the flow issues they can create, and practical ways to prevent or correct flow problems.

Properties of Solids

When analyzing solids for flow characteristics, there are five key properties that can affect how the solids will flow out of a hopper, bin or silo.

Cohesiveness

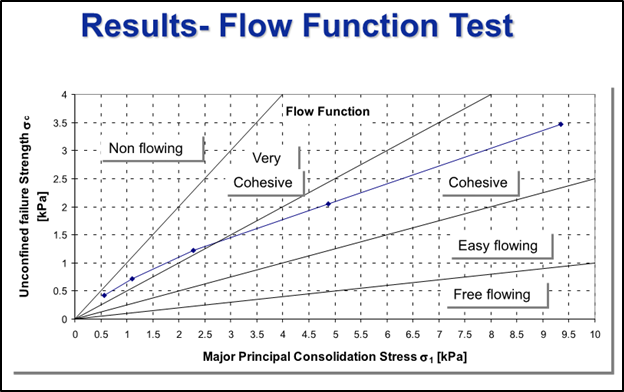

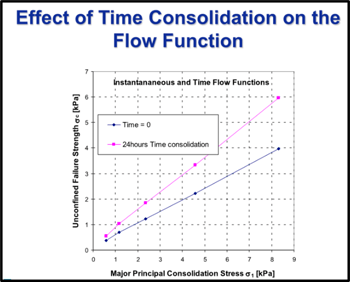

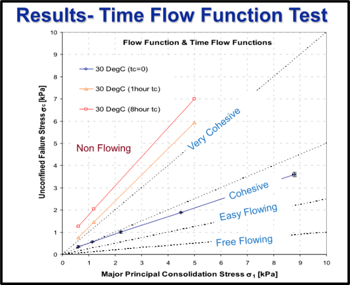

Cohesiveness measures a material’s resistance to shear stress (i.e. flow). It is determined by placing a sample of material under increasing downward pressure and measuring the shear (sideways) force required to overcome its internal resistance at each pressure. When graphed, the slope of the line drawn through these forces is referred to as the material’s “Flow Function.”

The results can be compared against known Flow Functions of other materials that range between non-flowing and free-flowing as shown below.

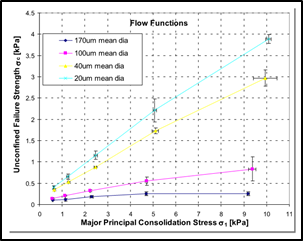

Increasing external pressure is not the only factor affecting a material’s cohesiveness and resistance to flow. Particle size distribution, shape, moisture content and time can also influence flow behavior.

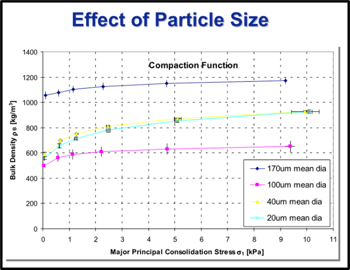

Compressibility

As solids are squeezed together by increasing force, they will naturally compact into denser mixtures with higher bulk densities. Although materials with different particle sizes may compress by a similar percentage, the resulting change in Flow Function tends to be more significant for smaller particles. This increased compressibility typically leads to greater internal cohesiveness and a higher likelihood of flow restrictions.

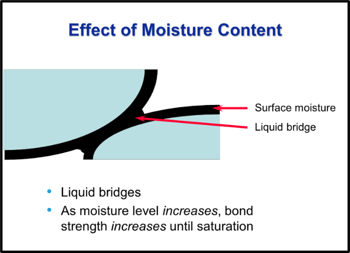

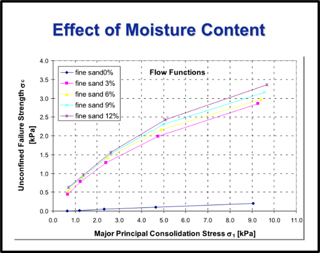

Moisture Content

Moisture can affect solids flow properties in different ways. Higher moisture contents generally result in increased adhesion between particles due to a combination of Van der Waals and electrostatic forces. While important, in most instances (but certainly not all), the effect of moisture on a material’s Flow Function is not nearly as great as most other factors discussed here.

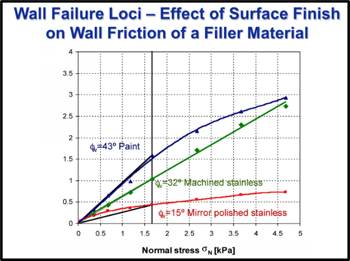

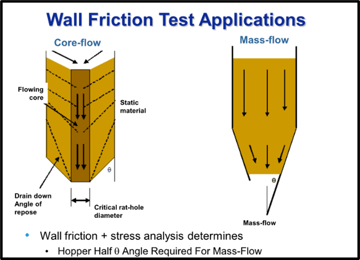

Wall Friction

Wall friction is the resistance to flow created by the hopper’s wall material and surface finish.It is measured as the angle of the slope of the Flow Function when different wall materials are used in testing. The smoother the wall finish, the lower the hopper wall angle must be for gravity to overcome frictional resistance between the wall and the solid particles.

Accurately determining wall friction helps specify the minimum outlet angle required for reliable mass flow.

Time

When solids remain under pressure for extended periods, they may compact and increase in cohesiveness (i.e. Flow Factor). This can result from particle rearrangement, plastic flow, moisture migration, chemical reaction, or electrostatic forces.

Time-dependent consolidation is a critical factor when designing hoppers or silos for specific materials, as it can significantly increase the risk of flow obstructions.

Common Solids Flow Issues

Solids flow issues typically arise when material does not flow through and out of a hopper or bin due to rat-holing or bridging.

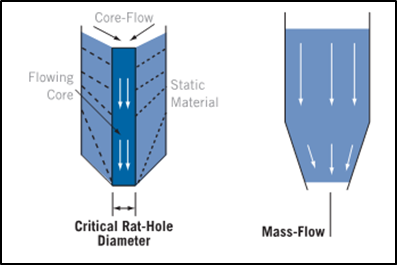

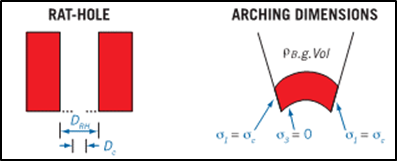

Rat-holing

Funnel (or core) flow occurs when the hopper discharge angle is not steep enough to allow the material resting on it to flow freely to the bottom outlet. This often results in a rat-hole forming directly above the hopper outlet, causing solids along the sidewall to remain in the hopper while fresher material passes through the central channel.

Rat-holing reduces usable capacity, increases material stagnation, and can compromise product consistency.

Bridging

Bridging occurs when internal cohesion exceeds the downward force acting on the material above the outlet. This results in arching (or bridging) of material across the opening.

Bridging often requires mechanical intervention or equipment redesign to restore proper flow.

Preventing Solids Flow Problems

As part of our material testing regimen, De Dietrich utilizes a Brookfield Powder Flow Tester (PFT) to measure and analyze solids properties discussed above. This information, combined with direct transfer testing, allows us to avoid solids flow issues and design flaws.

Accurate material characterization is the most effective way to engineer hoppers, bins, and silos that provide consistent, reliable solids flow and avoid common flow issues.

Get Expert Help Solving Your Solids Flow Challenges

Are you interested in learning more about the characteristics and flow properties of your solids? Contact us to discuss your material challenges or schedule an exploratory meeting so we can learn more about your process objectives and solids handling needs.