Understanding the NFPA's Guidelines on Pneumatic Conveying

Pneumatic conveying of solids is used in many industries to move bulk solids from one location to another through enclosed pipelines by using air or inert gas as the conveying medium. Given the importance of safety in such operations, the National Fire Protection Association (NFPA) has published comprehensive guidelines regarding the design and operation of pneumatic conveying systems.

Pneumatic conveying of solids is used in many industries to move bulk solids from one location to another through enclosed pipelines by using air or inert gas as the conveying medium. Given the importance of safety in such operations, the National Fire Protection Association (NFPA) has published comprehensive guidelines regarding the design and operation of pneumatic conveying systems.

Why is the NFPA's Involvement Important?

While oftentimes efficient, the process of pneumatically conveying bulk solids can also introduce potential risks. These risks primarily involve the possibility of generating and igniting dust clouds inside the system. Many materials, even those not typically considered combustible in larger bulk quantities, can become explosive when they are finely divided and suspended or dispersed in air.

Key Points from the NFPA Regarding Pneumatic Conveying:

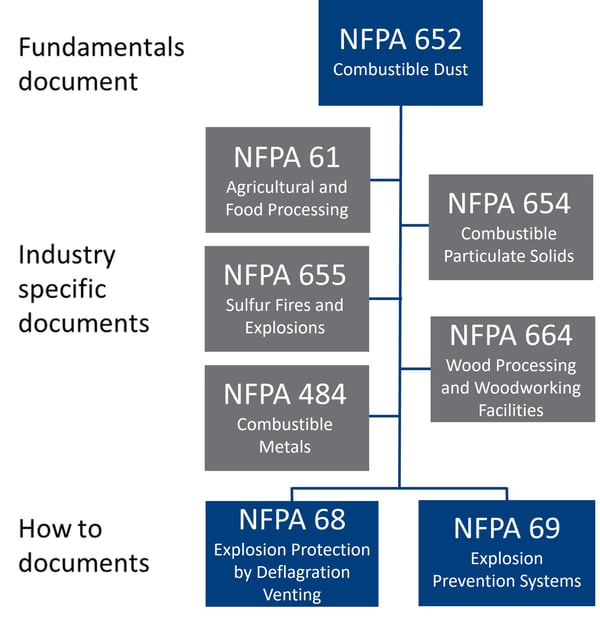

NFPA 652

This guideline contains fundamental rules and standards to address the risks of handling combustible dust. It provides many of the basic measures required to help prevent combustible dust fires and explosions and directs users to NFPA’s industry or commodity specific standards as well as standards on proper explosion mitigation and suppression practices. The diagram below represents the various documents available from the NFPA that are relevant to pneumatic conveying:

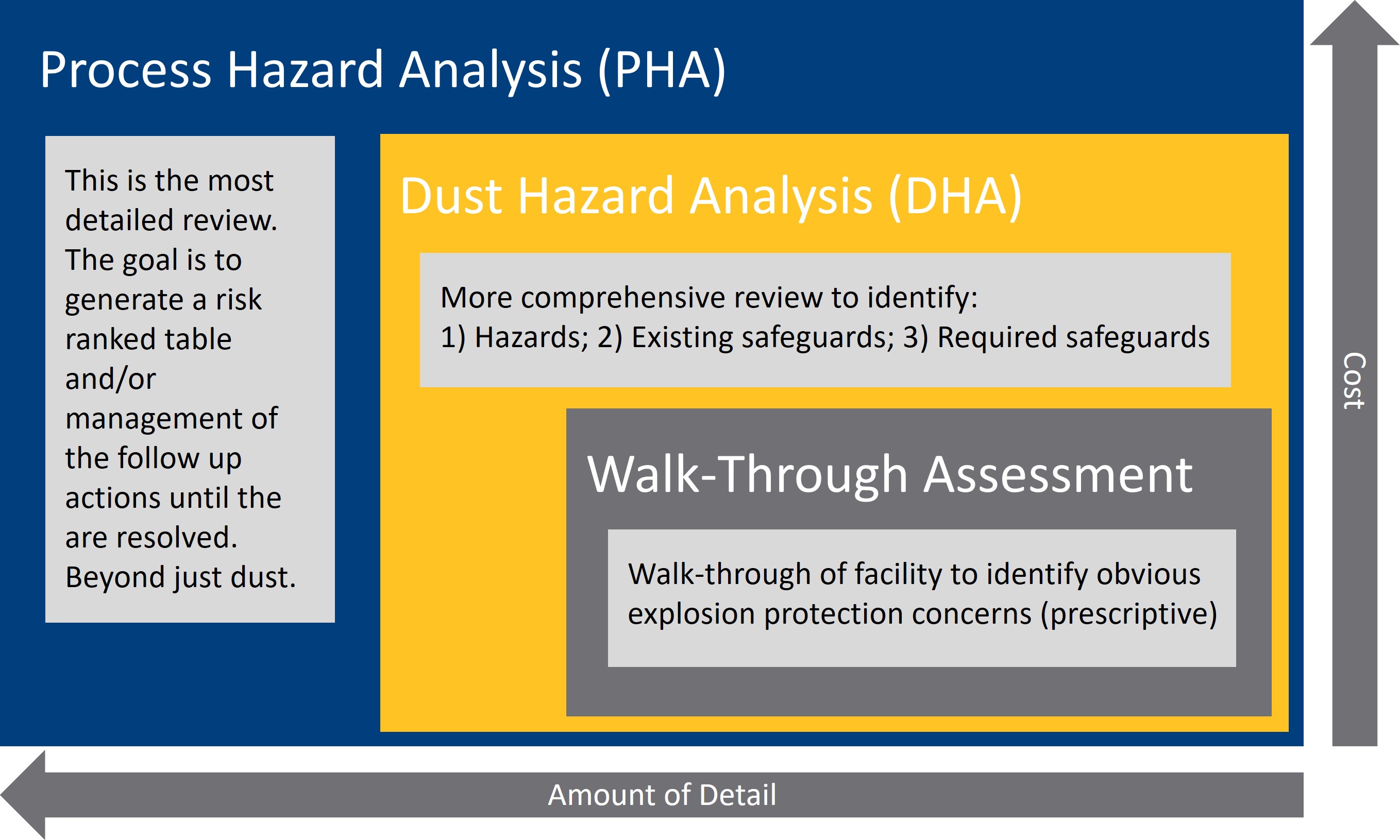

Dust Hazard Analysis (DHA)

A significant emphasis has been placed on the need for industries to conduct a DHA. Not to be confused with a PHA (Process Hazard Analysis), a DHA is normally incorporated within a PHA. This involves identifying and assessing potential fire, flash fire, and explosion hazards due to dust that is handled in a facility. For pneumatic conveying systems, the DHA would examine all parts of the system, from the feed point, through the convey line, separators, and receivers, to determine the risk of dust ignition. This graphic helps to detail how a PHA is related to a DHA and walk-through assessment in terms of cost and detail:

Housekeeping

Proper housekeeping and maintaining a clean facility is vital. NFPA standards mandate regular cleaning to prevent the accumulation of dust that could pose an explosion risk. There have been several recorded cases where dust accumulation along various flat surfaces have actually lead to secondary explosions, further increasing the damage caused.

Equipment Design

Components used in pneumatic conveying systems should be designed and installed to minimize the release of fugitive dust into the work area. Any equipment, including the conveying system itself, that can potentially provide an ignition source, should be designed to prevent this or be isolated from the conveying system. When pneumatically conveying almost any solid, chances are a static charge can accumulate within the system. This static buildup can become a primary ignition source if the equipment is not properly grounded. (For more information on addressing static electricity and the potential hazards it can present, please reference NFPA 77.)

Explosion Protection and Isolation

The NFPA recommends several strategies, including venting, suppression, and containment to provide explosion protection. It is important to ensure that explosion vents, if used, are directed to a safe location. Additionally, systems should be designed to prevent a fire or explosion in one part of the system from propagating to other parts. NFPA 68 and 69 provide detailed design information to address these concerns appropriately.

Training

Operators and maintenance personnel should be trained to fully understand the risks associated with combustible dust as well as the safe operation and maintenance of pneumatic conveying systems. Whether using a third party or working directly with the manufacturer of the system, it is essential for all parties involved to be educated on system usage and care. Allowing a time to ask questions and doing a physical walk-through of the system are two critical training exercises that will improve operator knowledge and minimize potential risks.

Monitoring and Control

Installing spark or ember detection systems can help in early detection and mitigation of potential ignition sources. These systems can be paired with extinguishing systems to quench sparks before they reach critical areas.

Conclusion

The NFPA's guidelines on pneumatic conveying are designed to help ensure that industries can leverage the efficiency of these systems while minimizing potential hazards. Following these guidelines can help prevent catastrophic incidents, and safeguard both infrastructure and human lives. Always remember, while the NFPA provides comprehensive standards, it's crucial to approach each conveying system individually, considering its unique characteristics and challenges.