Why We Love Borosilicate Glass (And You Should, Too!)

Borosilicate glass has been a preferred material of construction for virtually all modern laboratory glassware and glass process equipment for decades, with wide usage throughout the chemical and pharmaceutical industries. Its special properties of chemical and thermal resistances make it truly an exceptional glass with unique characteristics that distinguish it from other materials of construction. But how is it possible to feel warm and fuzzy about glass? Okay, maybe “love” is a bit too strong of a term to use, but we really, really like it and think you’ll find it pretty useful too.

Borosilicate glass has been a preferred material of construction for virtually all modern laboratory glassware and glass process equipment for decades, with wide usage throughout the chemical and pharmaceutical industries. Its special properties of chemical and thermal resistances make it truly an exceptional glass with unique characteristics that distinguish it from other materials of construction. But how is it possible to feel warm and fuzzy about glass? Okay, maybe “love” is a bit too strong of a term to use, but we really, really like it and think you’ll find it pretty useful too.

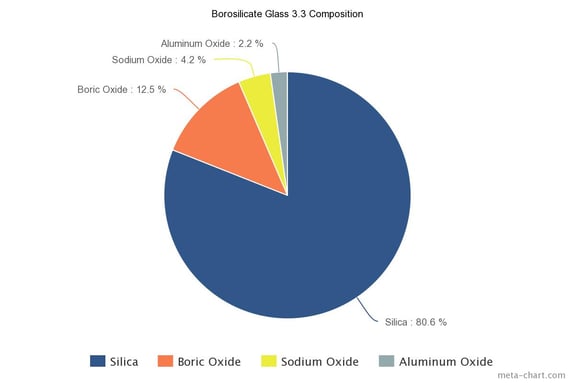

But before we get ahead of ourselves let’s take a step back for a moment and enroll in a speed course about Borosilicate Glass 101 (or technical speaking Borosilicate Glass 3.3). What is borosilicate glass and what makes it different from other types of glass? Common glass, such as window panes and every day kitchen drinking glasses, is typically a silicate glass that consists of sand, sodium-carbonate and limestone. The addition of boric oxide with silica is what differentiates borosilicate glass. The following chart details the chemical composition of QVF borosilicate glass 3.3:

The purpose of adding boric oxide is to create a less dense product with a higher melting point. The high temperature allowance and superior durability makes borosilicate glass useful for a variety of applications beyond process plants and pipeline including cookware, microscope and telescope lenses, stage lights, guitar slides, and art construction.

When it comes to chemical laboratory equipment and process plant components, the 8 major benefits that will have you loving borosilicate glass are:

1. Optical Clarity

It’s clear to see why glass is a good solution when it comes to visibility (how could I resist this pun). Compared to the array of plastics, metals and other materials of construction, glass provides a smooth surface that offers an unobstructed view of what is going on inside the equipment, enhancing the level of observation in any process. There is a slight decrease in transparency with the addition of Sectrans coating, an optional covering to the glass surface added for its protective properties against scratches, blows and splintering.

2. Cleanability

Some materials of construction can pose housekeeping issues when it comes to ease of cleaning. Not glass! The anti-stick, nonporous surface makes borosilicate glass a popular choice for GMP compliant applications. And its transparency allows you to see when equipment needs to be cleaned without the need for interrupting the process and performing an internal inspection.

3. Compact Design

Compared to systems built using alternative materials of construction, glass components are much more compact making a glass system significantly smaller. This is especially beneficial in facilities that are facing space constraints as well as work areas where headroom can become an issue. The compact arrangement can also make shipping, delivery, and installation easier.

4. Corrosion Resistance

Similar to the properties of glass-lined steel, glass equipment provides unsurpassed corrosion resistance to water, neutral and acidic solutions, concentrated acids and acid mixtures, and to chlorine, bromine, iodine and organic substances. Its resistance to chemical attack is superior to that of most metals and other materials, even during prolonged periods of exposure and at temperatures above 100 °C. There are only a few chemicals which can cause noticeable corrosion of the glass surface - hydrofluoric acid, concentrated phosphoric acid and strong caustic solutions at elevated temperatures. However, at ambient temperatures caustic solutions up to 30% concentration can be handled by borosilicate glass without difficulty.

5. Temperature Range

Borosilicate glass’ strong resistance to temperature makes it desirable in chemical and pharmaceutical processes. The maximum permissible operating temperature for QVF borosilicate glass is 200°C (due to limiting factors such as PTFE gaskets). Above a temperature of 525°C the glass begins to soften and above a temperature of 860°C it changes to the liquid state. Conversely, it can be cooled down to the maximum possible negative temperature, but is generally recommended for use down to – 80°C. An additional benefit within temperature allowance is the ability for borosilicate glass to be exposed to two different temperatures at the same time (though for safety reasons it is recommended that temperature difference does not exceed 100 K).

6. Structural Integrity due to Low Thermal Expansion

Directly related to the large temperature differential comes the benefit of low thermal expansion. Because borosilicate glass doesn’t expand like ordinary glass, there is a smoother transition between temperatures as well as the ability to withstand different temperatures at the same time. Borosilicate glass has an extremely low coefficient of linear expansion (3.3 x 10–6 K–1) as a result of its low thermal expansion. Additionally, the low thermal expansion coefficient eliminates the need for expensive measures to compensate for thermal expansion resulting from changes in temperature. This becomes especially significant in the layout of long runs of glass pipeline, ensuring a high level of structural integrity. For this reason, borosilicate glass is an approved and proven material in the construction of pressure equipment.

7. Affordability

Compared to other materials of construction that offer similar properties such as corrosion resistance, glass is relatively economical to produce. When compared to the other options such as quartz, glass is an extremely affordable solution. Its sustainability is an additional factor that adds to its affordability; with proper maintenance and care, your glass equipment can have a long life.

8. Inert Behavior

Because there is no interaction or ion exchange between the process media and glass, there is no catalytic effect. The inertness of borosilicate glass also means it is nonflammable and poses no environmental risk. Due to the inert behavior of QVF glass there is no smell or taste alterations and can therefore be used in an almost unrestricted way in pharmaceutical applications and in the food and beverage industry.

Just because glass can break when dropped or mishandled does not mean it is a weaker material of construction. Glass components have proven to be durable and reliable over many years of operation when installed and handled correctly. Here’s what we love about borosilicate glass - it’s clear, easy to clean, inert, economical, chemical and corrosion resistant and is a thermal champion. From laboratory/research and development up to full production, glass components and systems are available in a wide range of sizes and designs to build a custom solution based on the volume of your operation. These systems include (but are not limited to) reaction, distillation, extraction, evaporation, cryogenic and absorption systems.

QVF borosilicate glass parts and systems are all CE stamped and meet the highest credentials for conformity for quality. The strict manufacturing standards are performed by expert glass blowers at our state-of-the-art manufacturing facility in Mainz, Germany where it has been performed for well over a century. For more information about QVF SUPRA-Line visit our The World Of QVF SUPRA-Line webpage , contact us online, or call 908-317-2585.