Material of Construction Options for Process Equipment: Glass vs. Ceramic

When it comes to materials of construction for your process equipment there are many options, all with their own set of unique benefits. Two similar materials that are often compared to one another are glass and ceramic. Both are highly corrosion resistant, non-metallic, and have no metal components...but what sets them apart from each other? We'll do a quick comparison of the two materials in this post.

What is Ceramic?

What is Ceramic?

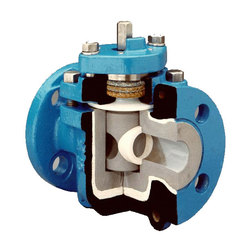

Ceramic is a crystalline solid composed of clay, minerals, and other natural materials. Its well-defined crystalline structure with highly-ordered atomic arrangement is what gives ceramic its strength and hardness. Ceramic is generally opaque, but some varieties with special processing can be translucent. Ceramic can withstand high compressive forces but is brittle when subjected to impact or stress. Ceramic has a high melting point and can withstand high temperatures without deformation, however once deformed it is not possible to reform to the prior shape.

Ceramic is used in a wide range of applications, from the home front (just take a look around your kitchen and bathroom!) to the industrial world (for things like electrical insulators), as well as high temperature applications in the aerospace industry.

What is Glass?

What is Glass?

Glass is a non-crystalline (or amorphous) solid, primarily composed of silica (sand) with other minor additives. Glass’s lack of ordered crystalline structure and irregular atomic arrangements provides glass with its unique properties. It behaves more like a supercooled liquid than a solid and its transparency is due to its amorphous nature. Additionally, glass is unique in that it undergoes a glass transition from a solid state to a rubbery/liquid state at higher temperatures. This glass transition is a reversible process that allows for glass to be formed into the many shapes that we use. Glass is brittle and can shatter easily with impact or stress and has low tensile and compressive strength. Glass has a lower melting point than ceramics and will soften and deform at a relatively lower temperature but can be reformed to its earlier shape with work.

Like ceramic, glass has many uses in a variety of household areas and personal products such as windows, kitchenware, phone screens and decorations. It is also used for industrial needs like sight glasses on a reactor, glass lining on a vessel, or an all glass 100% visual vessel.

Both glass and ceramic serve important functions in our world. Their unique properties set them apart from each other and make them perfectly suited to some of our most difficult applications, while their differences make them more conducive to difference uses (i.e. ceramic formed seal seat, and formed pieces, and glass-lined and formed vessels/ components). At De Dietrich, we offer a range of glass or glass-lined vessels as well as glass and ceramic components to meet a variety of needs for demanding service conditions. Contact us if you'd like to talk more about the range of material of construction options we offer for our equipment and systems.