- Systems

- Equipment

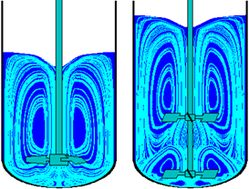

- Reactors

- Columns

- Filters and Filter/Dryers

- Powder Handling

- Mixing Systems

- Heat Exchangers

- Sampling Equipment

- Dryers

- Vacuum Pan Dryer

- Vertical Vacuum Dryer

- Horizontal Vacuum Dryer

- Horizontal Vacuum Paddle Dryer / Reactor

- Pilot Plant Filter Dryer and Vacuum Dryer

- Conical Screw Vacuum Dryer

- Conical Screw Mixer

- Conical Screw Cooker

- Cylindro Conical Dryer

- Cylindro Conical Mixer

- Pilot Plant BS-pilotDRY

- Laboratory System BS-miniDRY

- Universal Vacuum Dryers

- Rotary Vacuum Paddle Dryers

- Glass-Lined Conical Dryer-Blenders

- Spherical Dryers

- Agitated Pan Dryers

- Pipes, Valves and Fittings

- Storage Tanks and Receivers

- Reconditioned Equipment

- Evaporators

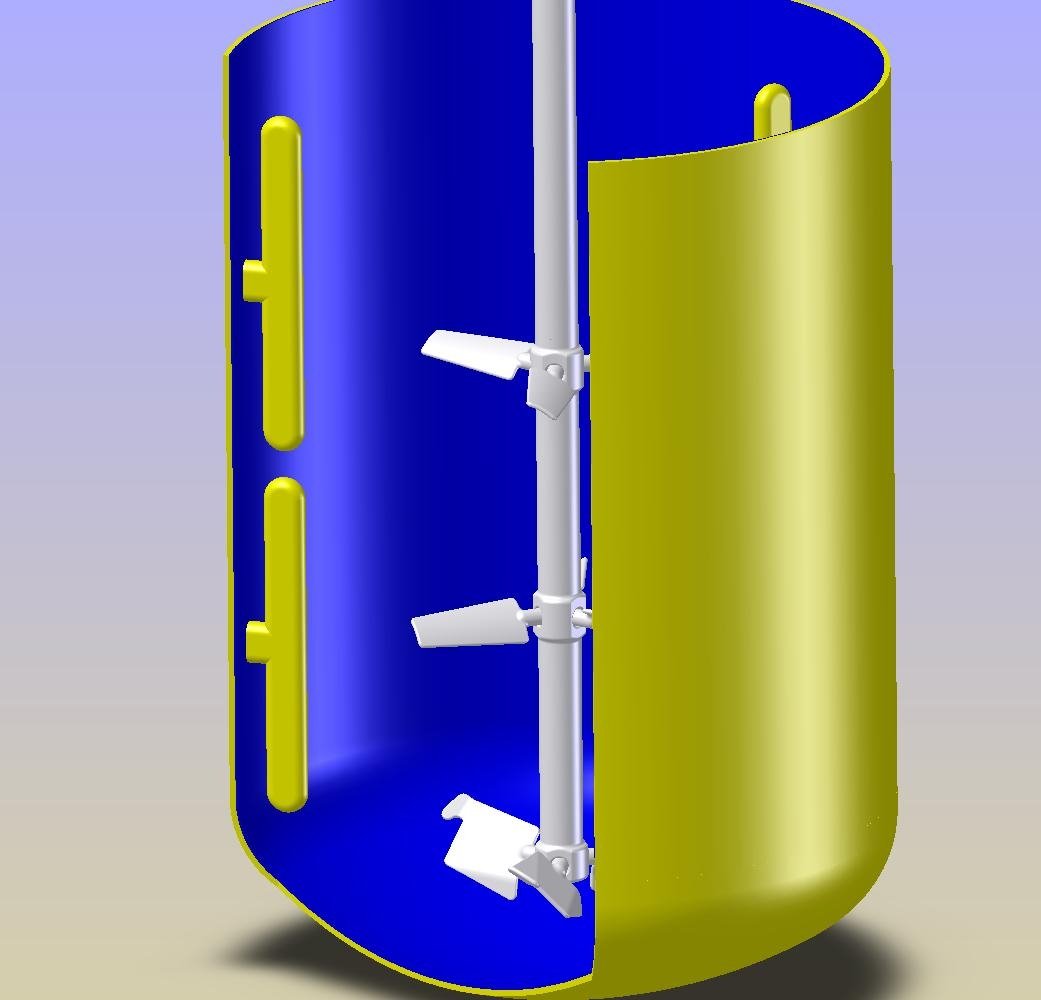

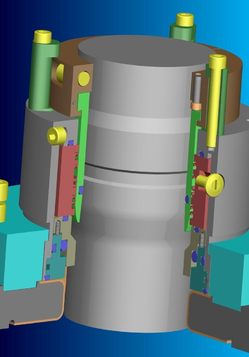

- Centrifuges

- Inverting Filter Centrifuge HF

- Inverting Filter Centrifuge F

- Horizontal Peeler Centrifuge Pharma

- Horizontal Peeler Centrifuge Chemical

- Vertical Peeler Centrifuge Pharma

- Vertical Peeler Centrifuge Chemical

- Vertical Peeler Centrifuge Gypsum

- Top Discharge Centrifuge Pharma

- Vertical Centrifuge Plasma Fractionation

- Top Discharge Centrifuge Chemical

- Classifying Centrifuge

- Coating Centrifuge

- Horizontal Pilot Plant Centrifuge Pharma

- Horizontal Pilot Plant Centrifuge Chemical

- Vertical Pilot Plant Centrifuge Pharma

- Vertical Pilot Plant Centrifuge Chemical

- Services

- Industries

- About Us

- Resources

- Contact Us