Ensuring Reliable Flow of Bulk Solids or Powders from Hoppers

When handling fluids, it has become quite easy to predict how they will flow. Just by knowing a few things like Reynold’s number, density, vapor pressure, viscosity, pipe roughness, etc., we can discern, with confidence, how that fluid will behave. For all those engineers out there reading this post, you might remember learning about these principles in your basic fluid mechanics class (because I'm sure everyone remembers everything they were taught in college!). Historical data and various tables are also readily available to support the design of liquid handling systems.

When handling fluids, it has become quite easy to predict how they will flow. Just by knowing a few things like Reynold’s number, density, vapor pressure, viscosity, pipe roughness, etc., we can discern, with confidence, how that fluid will behave. For all those engineers out there reading this post, you might remember learning about these principles in your basic fluid mechanics class (because I'm sure everyone remembers everything they were taught in college!). Historical data and various tables are also readily available to support the design of liquid handling systems.

Unfortunately, it’s not quite so simple when it comes to powders and other dry, bulk solids. Powders can develop ratholes and/or cause bridging in a hopper, often inhibiting product flow (this case study on transferring zinc oxide is a perfect example of that). Below are some pictures of what these flow obstructions could look like.

Product Properties

Although it more complicated, determining the flow of a solid can be done. One of the first steps is evaluating certain fundamental properties of your product. These properties are:

- Cohesive Strength (also referred to as "Unconfined Yield Strength") - The stress at which a sample of product under a specified load breaks and falls apart.

- Internal Friction - The resultant force caused by solids particles acting against each other.

- Compressibility - The relationship between a products bulk density and consolidation pressure. This basically helps us understand the amount of air within the spacing between solid particles.

- Wall Friction - The resultant force caused by solid particles flowing along a surface. To obtain accurate wall friction data, a coupon of the same material of construction for the hopper should be used for testing.

- Permeability - The measurement of a powder’s ability to maintain a pressure drop across it as gas is introduced through it.

Most of these properties can be determined using various types of shear cell testers. Each type of tester comes with its own integral software allowing easy adjustment of testing parameters, ensuring the most reliable results.

Evaluating Hopper Design Parameters

Once the information above is determined, relationships between these various properties can be established, providing sound data that can be used to recommend the optimal hopper design and bulk solids storage vessels. Specifically, this data can allow us to determine the following:

- Outlet diameter large enough to prevent arching, enable mass flow and ensure collapse in the event of a rathole formation

- Ideal outlet shape (square/round or slotted)

- Hopper angle to ensure mass flow or funnel flow

- Materials of construction best suited to provide stable gravity discharge

- Insight to determine if flow aids may be required due to spatial limitations

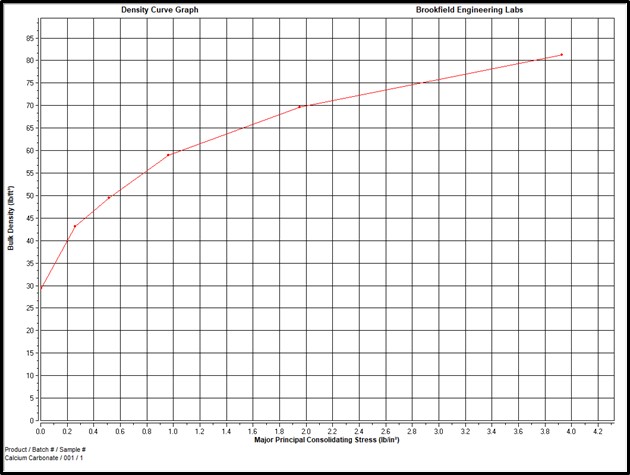

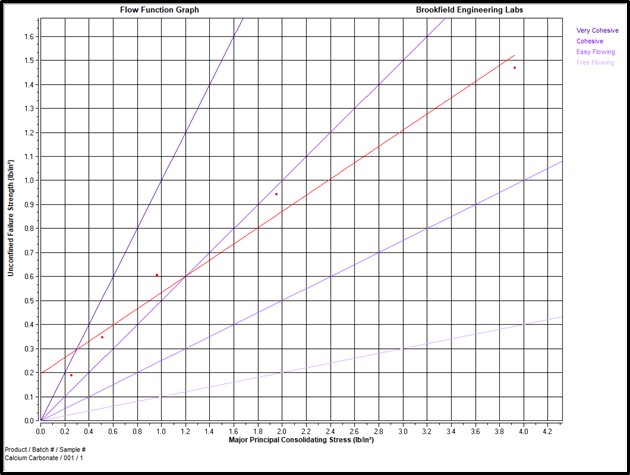

As an example of the data obtained when performing shear cell testing, below are some of the graphs showing the relationships between various properties. This data was obtained using a Brookfield PFT (Powder Flow Tester).

Figure 1: Bulk Density Graph – displays the bulk density of a sample of Calcium Carbonate at various consolidation stresses.

Figure 2: Flow Function Graph – displays how the cohesive nature of the material lessens under higher consolidation stresses. Data is plotted over standard flow indices to help determine what sort of properties the product would exhibit at the various consolidation stresses.

Through our experience handling powders and designing solids transfer systems, we've found that one primary way to ensure your solids flow properly is to use a hopper that is designed to maximize the efficiency of powder transfer. De Dietrich's SureFlow Bag Emptying Station was built to do just that. The unique cylindrical housing and conical hopper shape proves to be a superior alternative to traditional square hopper designs. These hoppers are available to complement our Powder Pump solids transfer system, providing customers with a complete solution for their material transfer needs. Contact us for more information.