New SureFlow Bag Emptying Station

For years, De Dietrich purchased bag dump stations from various manufacturers to integrate into some of our larger conveying system projects. Most units had the same basic design; a square hood with a dust collection system to help protect the operator and reduce fugitive dust, and a pyramidal hopper that transitioned from the bottom of the square box to a round outlet from which powder could be conveyed.

For years, De Dietrich purchased bag dump stations from various manufacturers to integrate into some of our larger conveying system projects. Most units had the same basic design; a square hood with a dust collection system to help protect the operator and reduce fugitive dust, and a pyramidal hopper that transitioned from the bottom of the square box to a round outlet from which powder could be conveyed.

Quite often however, cohesive powders would become lodged in the four corners or “valleys” of the pyramidal style hopper, and while flow aids such as mechanical vibration devices and friction-reducing gas injection systems did help powders flow down the side or end walls, they were generally not successful in removing powder from those valleys. Motivated by this problem, we began brainstorming a way to possibly eliminate it.

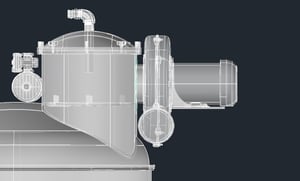

Based on previous experience, we already knew that smooth, steep-walled, conical style hoppers were much better than their square, flat-walled cousins at allowing cohesive powders to flow. However, mounting a round, conical hopper onto the bottom of a square box was not a viable solution as it created other areas for material to be held-up and would require more complex and expensive fabrication techniques. It quickly became obvious to us that a round, cylindrical housing on top of a conical hopper was a much better alternative than the traditional square design that we had been purchasing.

With that in mind, we began searching for a bag dump station of this design and were relatively surprised to find that it is a very rare animal indeed, as the overwhelming number of units on the market have square housings and hoppers. So, we decided to design and build our own!

The SureFlow Bag Emptying Station is now available to complement our Powder Pump solids transfer system, providing customers with a complete solution for their material transfer needs. Highlighted features and advantages include:

316 SS Materials of Construction

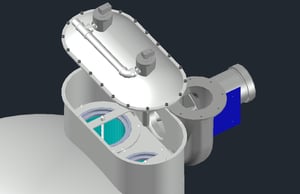

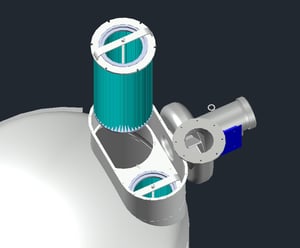

316 SS Materials of Construction- Minimal flat surfaces to reduce dust buildup

- Tool-free access to filters

- Can be mobile or stationary

- Removable grate

- Sliding door contoured shell design minimizes door footprint

- Pneumatic or electric controls for filter pulsing and outlet valve control

- Ability to hold 3-4 bags of material (depending on bulk density)

-

Class I & II, Division 1 or 2 ratings available

-

600 cfm spark resistant fan (with TEFC or XP motor & starter)

-

100 fpm induced air flow past operator to reduce fugitive dust exposure

-

45 ft2 of dust filter surface area

-

Pulse blow-back filter cleaning system

-

Isolation slide gate valve on hopper outlet

Download a copy of the SureFlow Bag Emptying Station data sheet or for more information contact us.