Unlocking Flow: A Deep Dive into Powder Handling Aids

Introduction: Why Powder Flow Problems Matter

In powder processing industries—from chemicals and pharmaceuticals to food and plastics—ensuring consistent and reliable flow of bulk solids is essential. Yet, powders are notoriously unpredictable. Their behavior depends on particle size, shape, moisture content, and even how long they’ve been stored. Issues such as bridging, ratholing, segregation, and adhesion can stop production in its tracks, cause inconsistent dosing, and lead to operator frustration or safety concerns.

Fortunately, there are a suite of flow aids to combat these challenges and keep powders moving. These devices and systems are designed to overcome material cohesion, reduce friction against vessel walls, and maintain a uniform, controlled discharge. Below, we’ll explore the most effective types of flow aids used in powder handling systems—and how to select the right one for your process.

Vibration: Simple, Reliable Flow Restoration

Vibratory flow aids are among the most widely used solutions for restoring movement in stagnant material. Mounted externally on hoppers, chutes, or silos, these units apply controlled oscillations to dislodge compacted powder and encourage discharge through the outlet.

Options range from pneumatic vibrators—ideal for hazardous or washdown environments—to electric vibrators that provide precise, variable-frequency control. Proper mounting and tuning are key: too much vibration can compact material further, while too little has no effect. When applied correctly, vibration provides a low-cost, maintenance-light solution for a broad range of powders and bulk solids.

Pneumatic Vibrator on Bag Dump Station

Air Pads & Fluidization: Turning Powders into Fluids

Fluidization cones or air pads/injectors introduce low-pressure air into the hopper cone, gently aerating and fluidizing the powder bed. This process temporarily transforms the material into a fluid-like state, enabling it to flow freely through the discharge point.

Fluidization works exceptionally well for fine powders (e.g., flour, alumina, lime, or soda ash) that tend to pack under their own weight. The injection of air not only reduces inter-particle friction but also decreases bulk density.

Proper airflow control is crucial to avoid over-fluidizing, which can lead to flushing or dusting. Integrating air pads with precision valves or programmable logic allows fully automated discharge sequences for consistent, repeatable results. Additionally, one other critical component to ensure success is that the gas/air being used is dry. As you could imagine, if the moisture content of your air is high, your chances of long term success drop drastically and you also risk reduced functionality of the flow aid itself.

Fluidization Cone with metallic membrane for uniform gas distribution

Ultrasonics: High-Frequency Flow Control for Difficult Powders

For highly cohesive or static-prone powders, ultrasonic systems such as those offered by Artech provide a modern, energy-efficient approach. These units use high-frequency vibrations transmitted through hopper walls or discharge cones to break internal friction bonds within the powder bed.

Unlike mechanical vibration, ultrasonics operate at a frequency several orders of magnitude larger, producing a continuous “micro-vibration” effect that keeps material moving without agitation or noise. The goal with this device is to detect a certain resonance within the discharge cone and target that frequency for optimal results. They’re particularly suited for titanium dioxide, PVC resins, and other fine or electrostatically charged powders that resist traditional flow methods.

Because they can be automated and installed without modifying the vessel geometry, ultrasonics are a valuable upgrade for both new and existing systems.

Ultrasonics installed on hopper wall

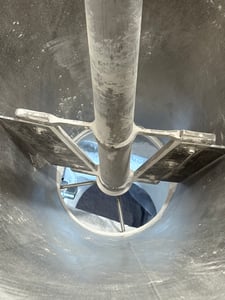

Mechanical Agitation: Direct Action for Sticky Materials

In certain applications, the best way to maintain flow is through direct mechanical action. Agitation paddles, screws, or rotating arms inside the hopper actively stir or sweep powder near the discharge point, preventing compaction and ensuring even feed to downstream equipment.

Mechanical agitation is ideal for cohesive, sticky, or damp materials—those that vibration or air pads can’t easily free. Systems can be designed for gentle or aggressive motion depending on material sensitivity, and they’re often integrated into bulk bag unloaders or cone-bottom silos.

While these systems involve moving parts and require more maintenance, their performance in difficult applications can justify the investment.

Custom impeller for agitation system in hopper

Bag Massage/Conditioning: A Smart Solution for Bulk Bag Unloading

For flexible bulk containers (FIBCs), bag massage and conditioning systems are a simple yet highly effective solution. Pneumatically or sometimes hydraulically actuated paddles or plates gently press against the sides of the bag, loosening compacted powder and restoring free flow toward the outlet spout.

This system is especially useful when unloading powders that compact during shipping or storage—such as pigments, starches, or fine chemicals. By automating the massage sequence, operators can reduce manual intervention, improve ergonomics, and speed up discharge cycles.

When it comes to implementing these techniques, massage is often incorporated within a bulk bag unloading station itself. Conditioning, however, is usually provided in a stand-alone piece of equipment that provides better access to the bag and a more aggressive approach to breaking up the solids inside the bags. You may see conditioning implemented in cases where a material is hygroscopic and is stored for longer periods in an unconditioned area or outside which normally leads to product packing or solidification.

Bag Massage on Bulk Bag Unloading Station

How to Choose the Right Flow Aid

No single flow aid suits every application. Selecting the optimal solution requires understanding both the material behavior and the process environment. Key factors include:

- Material properties: Cohesiveness, particle size distribution, compressibility, and moisture sensitivity all influence flowability.

- Equipment design: Hopper geometry (wall angle, outlet diameter, hopper type, surface finish, etc.) affects how easily powder discharges.

- Process requirements: Consider batch vs. continuous operation, automation level, and whether gentle handling is needed to avoid degradation.

- Safety and hygiene: In food and pharmaceutical processing, flow aids must comply with strict standards for cleanliness, contamination control, and static discharge.

Testing and Validation: The Value of Pilot Trials

Whenever possible, testing is essential. Pilot-scale trials—such as those available at the De Dietrich test facility in Swedesboro, NJ—allow you to evaluate real materials under realistic conditions. Flow property analysis, discharge testing, and equipment trials can help determine which flow aid or combination yields the most reliable performance.

Conclusion: Improving Efficiency Through Better Flow

Flow aids are not mere accessories—they’re vital enablers of process reliability and productivity. By addressing flow issues proactively, manufacturers can reduce downtime, minimize waste, and maintain consistent product quality.

Whether you’re handling fine powders, sticky resins, or cohesive intermediates, integrating the right flow aid can transform your powder-handling system from a bottleneck into a streamlined, efficient operation.

Contact De Dietrich to discuss your powder handling challenges and schedule a material trial at our testing facility. Together, we’ll help you design a solution that keeps your process flowing smoothly.