Distillation Columns and Internals for Today's Process Challenges

(Note: This article was derived from Chemical Engineering Magazine’s April 2019 article Distillation: It’s What’s on the Inside that Counts by Joy LePree, featuring De Dietrich. For more information and to see the original article in its entirety, click here.)

Distillation columns are the primary equipment used in the chemical process industry to carry out the separation of organic chemicals. Typically, the distillation tower does not stand alone; it is usually connected to upstream and downstream equipment that, together, make up a comprehensive process system. Therefore, the more efficient and reliable the distillation column is, the better the entire system performs.

Distillation columns are the primary equipment used in the chemical process industry to carry out the separation of organic chemicals. Typically, the distillation tower does not stand alone; it is usually connected to upstream and downstream equipment that, together, make up a comprehensive process system. Therefore, the more efficient and reliable the distillation column is, the better the entire system performs.

Most problems that you’ll encounter with columns are likely related to inefficiencies, bottlenecks, and/or unexpected shutdowns. These complications can negatively impact the rest of the plant, reducing production and yield. To overcome these difficulties, new breakthroughs in column internals are being researched and current technologies are being improved to help optimize their efficiency and keep units running longer. The outcome is not only a more reliable mass transfer performance, but a more cost-effective operation.

Common Column Issues

Distillation columns are known for their propensity to consume large amounts of energy, among other challenges. The main bottlenecks that hinder the separation process are:

- Fouling – Multiple factors, either independently or together can cause fouling tendencies in columns. Vaporization of volatile chemicals, droplet formation from condensation, and corrosion-inducing chemical reactions are just some of the phenomena that occur inside a column, making the packing and other internal components susceptible to fouling.

- Mechanical Issues – Equipment vibrations can cause column components to shift over time or even cause mechanisms within the columns to come apart, resulting in damage to the internal structures.

- Internal Pressure Reduction – Reduced separation efficiency can result from low vapor flow which leads to a drop in pressure inside the column. If the pressure exerted by the vapor is insufficient, it won’t hold up the liquid on the tray, resulting in the leakage of liquid through the column internal’s perforations. This is known as “weeping” and can be detrimental to the purity of your distillation, sometimes requiring the batch to be reprocessed.

- Foaming - Although it is not as prevalent as other issues, foaming can occur in situations when the liquid expands and changes into vapor or gas at too high of a velocity and evaporation rate. Design, condition and placement of the trays in the column can also attribute to the foaming problem. In fact, if trays are too close together, entrainment can occur (i.e. foaming fluid in a lower tray mixes with the liquid on the above tray).

All of the above issues can have a direct effect on the handling capacity of your distillation column.

New Solutions for Column Internals

Technologies to curtail these issues and increase energy efficiency are at the forefront of column R&D, both for the customer and the distillation equipment manufacturer. These problems can be very expensive to fix, due to the efforts that need to be taken to shut down the equipment (often upstream and downstream equipment must be shut down as well since they are connected to the column). To aid processors in increasing energy efficiency and reliability, some of the recent solutions include:

- Replacing conventional trays and packings with newer, advanced solutions - This can be done in a variety of ways including replacing random packing to increase efficiency and tower capacity as well as installing high performance packing. Process engineers have also started blending different sized packing in order to get benefits of both components – the efficiency of smaller-sized packing and the retainment of capacity and pressure drop with the larger packing size. This solution is recommended for absorption and stripping, fine chemical distillation, refinery fractionators, and retrofit projects.

- Anti-fouling equipment for difficult conditions – Foul-resistant trays, grid packings, and valves can provide high-performance for capacity and efficiency and are suitable for highly fouling distillation applications. You should request this “severe service” type of column internals if your application has fouling sensitivities.

Specialized Solutions

Often, distillation systems are unique in their requirements, so the challenges are specific to each customer and therefore must be addressed individually. Customized solutions are available to enable wider operating ranges, higher capacity, and other demands to provide more flexibility. By combining upgraded features and new technologies, process engineers can provide an arrangement of column internals to address specific process objectives based on the customer’s focus.

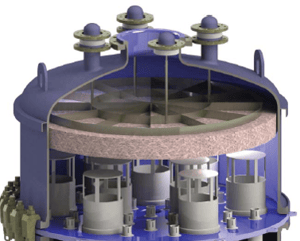

De Dietrich focuses on providing columns and internals for highly corrosive processes at temperatures up to 390°F. Columns up to 40 in. diameter are made of QVF borosilicate glass 3.3 or De Dietrich glass-lined steel. Bigger columns up to 84 in. diameter are made of glass-lined steel only. The corrosion-resistant materials are comprised of borosilicate glass, SiC, PTFE or Tantalum. For processes exceeding 300°F, SiC is mandatory over PTFE due to its higher temperature resistance. SiC also permits the design of bigger distributors and collectors that are less sensitive for feeds containing solids or those that have a tendency to foam, degas or to flash.

De Dietrich Durapack structured packing in borosilicate glass 3.3 is suitable for corrosion resistant glass or glass-lined steel columns as it has the same corrosion resistance as the column’s material of construction and keeps its thermal stability at higher temperatures compared to PTFE and other comparable polymers. Unlike traditional ceramic packing, borosilicate glass is non-porous, which substantially cuts erosion and corrosion.

New technologies for distillation column internals aim to reduce pressure drop, maximize capacity, and minimize fouling sensitivity. By improving efficiency and reliability of distillation towers you can substantially reduce capital expenditures while improving your production. To find out more about the technologies and specialized solutions De Dietrich can offer you in the design, engineering, and commissioning of a distillation column (along with a process guarantee), fill out our Column Internals Questionnaire. Or, if you are interested in learning more about our column capabilities, download our Process Solutions for Mass and Thermal Media brochure or request to speak with one of our sales engineers.