What is Thermal Shock - and the Do's and Don'ts to Avoid It

Thermal shock is damage or failure caused by a rapid change in temperature. When materials are heated, they expand; when cooled, they contract. If a sudden and significant temperature change occurs, the outer surface of a material may expand or contract faster than the inner layers, creating internal stress that can lead to cracking or failure.

Thermal shock is damage or failure caused by a rapid change in temperature. When materials are heated, they expand; when cooled, they contract. If a sudden and significant temperature change occurs, the outer surface of a material may expand or contract faster than the inner layers, creating internal stress that can lead to cracking or failure.

Most of us have experienced thermal shock in everyday life. For example, removing a hot glass baking dish from the oven and placing it into a sink containing ice or cold water can cause it to crack instantly—an unfortunate but familiar lesson in rapid temperature change.

While glass is often the first material people associate with thermal shock, all materials are susceptible, though some are more resistant than others. Based upon the materials of construction, design, and fabrication methods, all process equipment are rated to a maximum permissible thermal shock value, which defines the allowable temperature differential between the inside and outside surfaces of said equipment.

The effects of thermal shock vary by material. In some cases, it can cause immediate structural failure; in others, it may introduce stress that shortens equipment lifespan. In all cases, however, thermal shock presents a potential safety hazard and can result in costly downtime. Following best practices is the most effective way to reduce risk.

Do’s for De Dietrich Glass-Lined & Glass Equipment Thermal Shock Prevention

- Know your vessel’s operating limits

Always check the nameplate for maximum allowable pressure and temperature. Keep in mind that accessories such as seals and valves may have lower limits that govern overall operation. - Heat and cool gradually

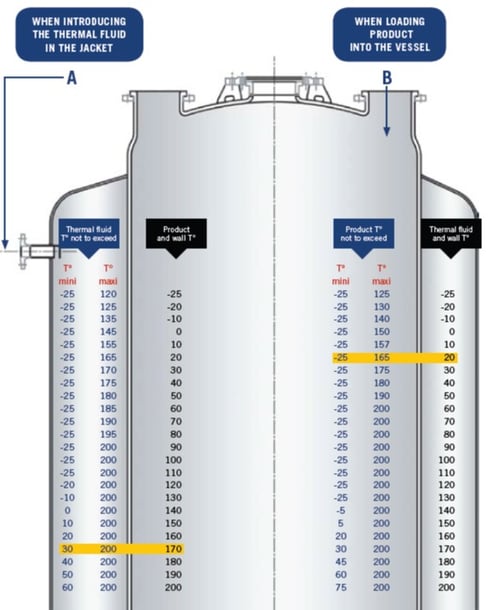

Introduce temperature changes slowly to minimize thermal stress on the material. Our Thermal Shock Allowance Chart for glass-lined vessels is an essential resource when introducing product or thermal fluid into the vessel or jacket, respectively:

Rapid changes in temperature across the walls for borosilicate glass should also be avoided during operation both on interior and exterior/jacket. The result in increase thermal stress. In general for De Dietrich's QVF Supraglass, a maximum permissible thermal shock value of 120K/ 120C can be taken as a general guideline for single shell components. Jacketed glass vessels & glass coil heat exchange equipment have decreased values per our literature.

The following operating data are the basis for the wall thickness calculation (for unjacketed items).

| Operating Temperature | TS = 200°C |

| Temperature differences between inside and outside | ΔΘ ≤180 K |

- Use proper circulation

Ensure fluids circulate evenly to prevent localized hot or cold spots that could crack or damage the lining. - Follow manufacturer guidelines

Adhere to De Dietrich’s recommended procedures for startup, shutdown, cleaning, and operation. - Inspect equipment regularly

Look for early signs of damage such as discoloration, crazing, or cracks so issues can be addressed before they escalate.

Don’ts for De Dietrich Glass-Lined & Glass Equipment Thermal Shock Prevention

- Don’t exceed allowable temperature differentials

Avoid sudden exposure to large temperature changes, such as adding cold liquid to a hot vessel. - Don’t ignore accessory limits

Even if the vessel itself can tolerate higher temperatures, weaker components may fail and cause damage. - Don’t allow freezing conditions

Water or condensation trapped in jackets, nozzles, or baffles can freeze, expand, and crack glass or damage equipment. - Don’t use improper cleaning methods

Avoid high-pressure cold water or steam shocks during cleaning operations. - Don’t forget about the environment

Room temperature should be considered when calculating acceptable internal operating temperatures. - Don’t skip training

Operators unfamiliar with glass-lined or borosilicate glass equipment may unintentionally introduce thermal stress through unsafe practices.

Why It Matters

Thermal shock can cause irreversible damage, leading to unplanned downtime and potential safety risks for operators. By following these do’s and don’ts, companies can extend equipment life, improve safety, and maintain process integrity.

While this article focuses on two De Dietrich product lines, these principles apply broadly across our portfolio. Additional product-specific guidance is available:

- QVF Borosilicate Glass

To avoid irreversible cracking that leads to component replacement and downtime, please review Chapter 1 – Technical Information in the Supra Catalog. - Glass-Lined Steel Equipment

To avoid irreversible cracking and spalling that can result in costly reglassing, please refer to the maximum allowable thermal shock chart in the 3009 Glass Brochure and the Maintenance Manual for De Dietrich Glass-Lined Steel Equipment. - Alloy Equipment (Filter/Dryers, Solids Handling, Centrifuges)

To prevent metal fatigue and reduced service life, consult the applicable operating manuals.

For any De Dietrich equipment, if you are ever unsure about acceptable operating conditions, it is always best to consult a De Dietrich professional who can provide the appropriate guidance.