New Fabrication or Reglassing? A Strategic Analysis of Cost, Customization, and the ESG Imperative

When a mission-critical glass-lined reactor reaches the end of its service life—whether due to corrosion, glass failure, or mechanical damage—the decision facing a Plant Manager or Capital Project Lead can have sweeping implications. What was once a straightforward cost comparison between repair and replacement has evolved. Today, capital-equipment decisions must be filtered through a broader lens: sustainability targets, operational efficiency, and the conservation of embodied energy.

Choosing between reglassing, purchasing a reconditioned vessel, or fabricating a brand-new reactor involves balancing three core variables: Total Cost of Ownership (TCO), Operational Downtime, and Process Customization. This post examines each option through that strategic decision matrix and explores the ESG impact behind the choice.

The ESG Rationale: Why Restoration Is More Than a Cost Decision

The Embodied Energy Imperative

Every reactor carries a large environmental “upfront cost” in the form of embodied energy—the cumulative energy required to extract raw materials, smelt and form the steel, fabricate the shell, and apply the glass lining. Most of a vessel’s lifetime environmental burden occurs before it ever enters service.

Choosing restoration over replacement allows companies to bypass a significant portion of this energy expenditure. In a time when ESG goals are shifting from aspirational to measurable, this makes reglassing or reconditioning not just operational decisions, but strategic sustainability actions.

Saving the Carbon Steel Substrate

When a vessel is reglassed, the carbon-steel shell remains in place—a massive source of value and energy savings. Reglassing eliminates the need for:

- Smelting and casting virgin steel, one of the most energy-intensive industrial activities.

- Rolling and forming large-diameter shells, which require heavy industrial machinery and transport.

- Precision welding, a labor-intensive process that consumes energy and requires highly skilled fabrication labor.

Preserving the substrate avoids unnecessary manufacturing impacts and keeps a high-value pressure vessel in the economic cycle.

A Circular Economy Approach

Both reglassing and reconditioned vessels directly support circular-economy principles. Instead of prematurely retiring a vessel that still has structural integrity, restoration extends its service life—often by multiple decades. This prevents waste, preserves embodied carbon, and reduces demand for newly fabricated steel assets.

Option 1: Reglassing Your Vessel

Maximum Value, Maximum Sustainability

Ideal For: Facilities focused on minimizing capital expense and achieving the longest possible lifecycle from equipment known to perform well in its current setting.

Why It’s the Cost Leader: Reglassing is the most cost-effective solution—typically 40% to 50% of the cost of a new vessel. For companies prioritizing capital conservation, it represents unmatched ROI.

The Trade-Off: Mandatory Sequential Downtime. The one unavoidable drawback: the vessel must be out of service during the entire reglassing process. This includes:

- Removal and transport to the De Dietrich facility in Corpus Christi, TX

- Full blast, inspection, and Non-Destructive Examination (NDE)

- Repair, reglassing, and reassembly

- Return shipment and installation

For high-throughput or continuous processes, this downtime may carry significant financial consequences. That cost must be weighed against the capital savings.

Requirements for Eligibility: Not every vessel can be reglassed. The steel shell must demonstrate structural integrity after NDE. When a shell passes inspection, reglassing provides a “like-new” piece of equipment with a significantly extended lifespan.

Option 2: A Reconditioned Vessel

Zero Downtime, Rapid Deployment, ESG-Friendly

Ideal For: Plants where production uptime is the highest priority, and any sequential shutdown carries steep economic consequences.

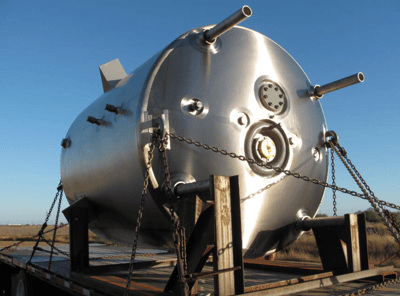

The Downtime Eliminator: A reconditioned vessel solves the biggest challenge of reglassing. De Dietrich maintains an inventory of shells that have undergone full structural evaluation, refurbishment, and glass relining. These vessels are ready for immediate installation.

This allows plants to:

- Swap the unit with zero sequential downtime

- Maintain production continuity

- Still capture major cost and sustainability benefits by reusing an existing shell

Cost and Availability Considerations: This solution typically costs 65% to 70% of a new vessel—higher than reglassing your own but still far below new fabrication. Availability is the defining variable; the candidate vessel must match your required:

- Working volume

- Pressure rating

- Design / configuration

When a suitable match exists, this option delivers unmatched speed and minimal disruption.

Option 3: New Vessel Fabrication

Optimization, Performance, and Future-Proofing

Ideal For: Process engineers seeking improved performance, flexibility, or new capabilities that existing designs cannot support.

The Cost: A new vessel requires full capital expenditure—100% of the cost—but it provides complete freedom to engineer the ideal system.

The Unique Advantage: Total Design Customization. New fabrication allows process engineers to rethink the vessel from the ground up, including:

- Nozzle size and placement for improved charging, instrumentation, or sampling

- Jacket configuration optimized for heat transfer and cycle time

- Vessel volume or H/D ratio changes to support new reaction kinetics, scale-up needs, or improved mixing performance

For processes undergoing modernization or expansion, these design parameters are often decisive.

Regulatory & Documentation Benefits: A newly fabricated vessel comes with full ASME documentation, a fresh lifecycle baseline, and a complete traceability package—valuable for regulated environments such as pharmaceutical and specialty chemical manufacturing.

Three Options, One Mission—Strategic Alignment

Each path offers a different strategic advantage:

- Choose reglassing your vessel if cost savings and sustainability are the top priorities and downtime is manageable.

- Choose a reconditioned vessel if avoiding production interruptions is paramount and a matching unit is available.

- Choose new fabrication when process improvements or future scalability require full design flexibility.

No matter the choice, De Dietrich can guide you through a structured evaluation that aligns operational needs with ESG commitments and capital strategy.

Next Steps

Contact our team to schedule a Reglassing Assessment, fill out our reglassing questionnaire online or request a review of our current inventory of reconditioned vessels to find the right solution for your facility.